Tap thumbnails to view different images

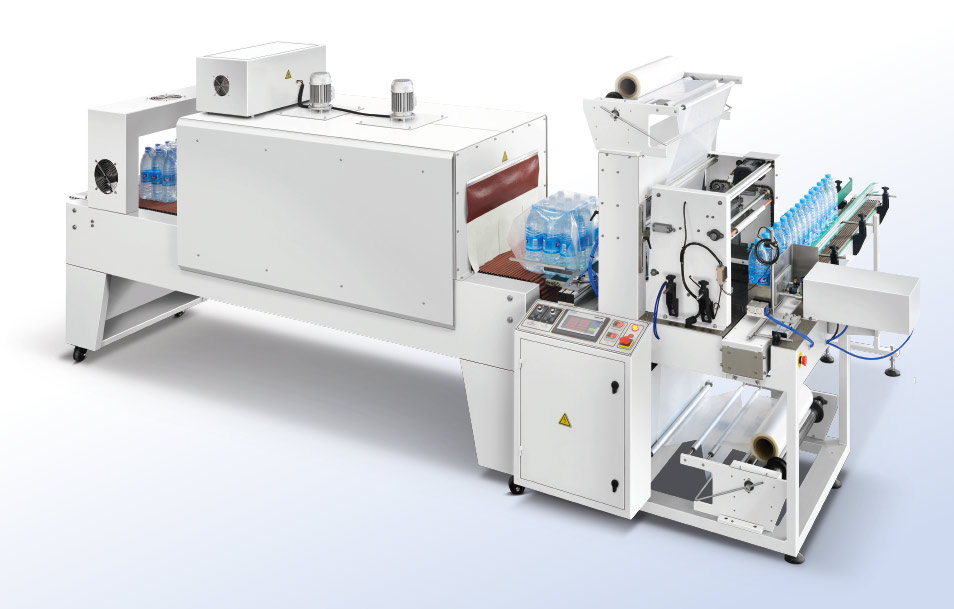

SK-080A Automatic Sleeve Shrinking Machine

SK-080A automatic sleeve type shrink wrapping machine for bottle packing. Features Siemens PLC, 8-18 packs/min, 380V power, and customizable configurations for efficient B2B operations.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The SK-080A automatic sleeve type shrink wrapping machine is designed for fully automatic bottle bundle packing, handling feeding, wrapping, sealing, shrinking, and cooling without manual assistance. It supports various configurations such as 10 bottles (1x10), 9 bottles (3x3), and up to 24 bottles (4x6), making it ideal for high-volume production lines.

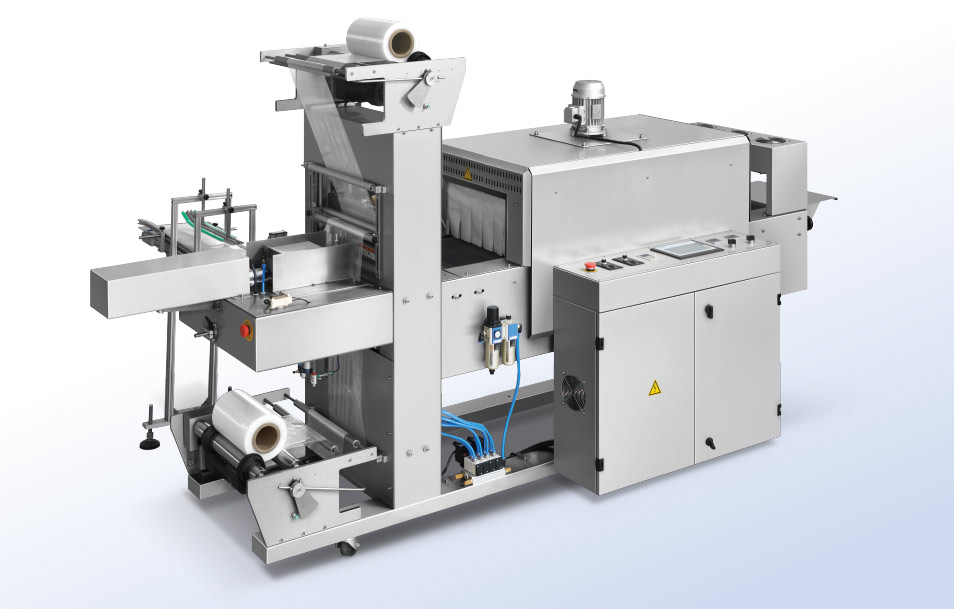

Built with world-leading technology, this machine ensures reliable and safe operation, integrating Siemens PLC and programmable controllers for seamless electrical, mechanical, and pneumatic system coordination. It offers flexibility with options for multiple packing lines and easy switching between configurations using a rotating switch.

Features include a worm gear reducer for vibration-free operation, a Teflon-coated sealer for secure seals, and a PE conveyor for durability. The machine also includes a double wind engine for even heat distribution, a strong cooling system, and customizable feeding fixtures and conveyor directions to suit specific workplace requirements.

Key Benefits

- Fully automatic operation with no manual assistance required

- Siemens PLC and programmable controller for integrated control

- Flexible packing configurations (e.g., 10, 9, 12, 15, 24 bottles)

- Worm gear reducer for vibration-free in-feeding and film feeding

- Teflon-coated sealer for secure, non-stick sealing

- PE conveyor with high anti-abrasion and strength

- Customizable feeding fixtures based on bottle shape

- Color coding system for positioning with colorful materials

- Modular design for quick exchange when bottle shapes change

- Adjustable conveyor direction (right or left side in-feed)

- Double wind engine for even heat distribution

- Silicon rubber-covered rollers for extended conveyor life

- Frequency converter for adjustable conveying speed

- Strong wind cooling system for instant product cooling

- Optional roller table to prevent product falling

SK-080A Automatic Sleeve Shrinking Machine Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Model | SK-080A |

| Sealing Type | Sleeve sealing |

| Max Product Size | 420(L) x 300(W) x 300(H) mm |

| Film Type | Polyethylene (PE) film |

| Max Film Size | 600(width) x 280mm (outer diameter) |

| Tunnel Oven Size | 1800mm(L), entrance 600(W) x 400(H) mm |

| Tunnel Conveyor | Chains with silicon coated rods |

| Working Height | 850-900mm |

| Air Pressure | ≤0.5MPa (5 bar) |

| Sealing System | Durable 'U' shape alloyed sealing knife and saw teeth cutting knife with anti-stick Teflon coats |

| Operating Panel | Siemens colorful touch screen, PLC, Omron temperature controller |

| Machine Material | Carbon steel |

Frequently Asked Questions

Common questions about SK-080A Automatic Sleeve Shrinking Machine and our services.

Q:What is the maximum product size the SK-080A can handle?

Q:How many packs per minute can this machine produce?

Q:What type of film is compatible with this shrink wrapping machine?

Q:Is the SK-080A easy to integrate into existing production lines?

Q:Can the conveyor direction be adjusted?

Related Products

SK-060ABS Automatic Sleeve Type Shrink Bundling Machine

SK-060BBS Fully Automatic Sleeve Shrinking Machine

SK-060CBS Fully Automatic Sleeve Shrinking Machine

SK-060EBS Fully Automatic Shrink Bundling Machine

Ready to Upgrade Your Production Line?

Get a customized quote for SK-080A Automatic Sleeve Shrinking Machine and discover how it can optimize your operations.