Tap thumbnails to view different images

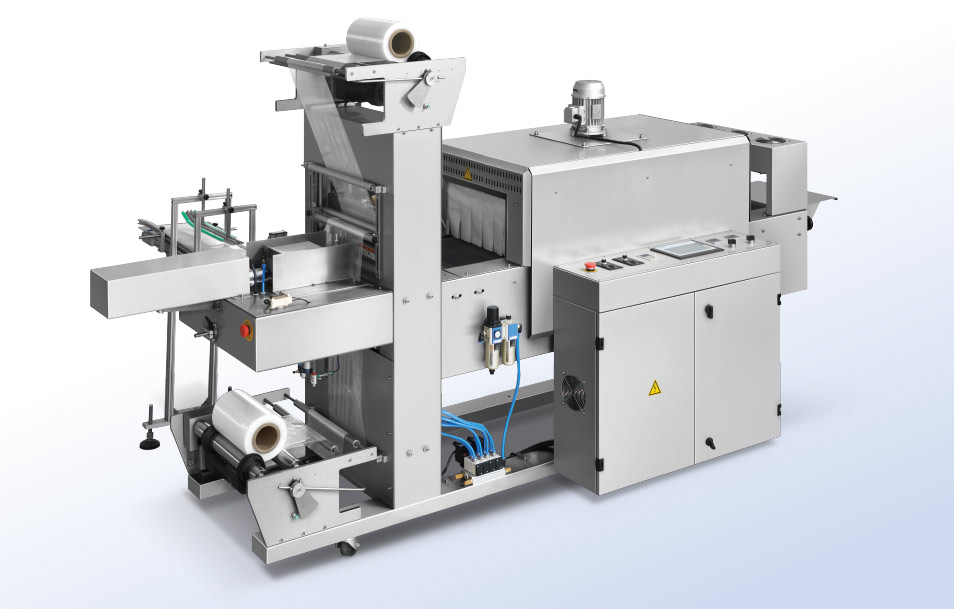

SK-060CBS Fully Automatic Sleeve Shrinking Machine

SK-060CBS fully automatic sleeve packing machine offers reliable, safe packaging with Siemens PLC control, heat shrinking, and customizable options for various production lines.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The SK-060CBS fully automatic sleeve packing machine is engineered for single or multiple cylinder packaging, seamlessly integrating with production lines to automate feeding, wrapping, sealing, shrinking, and cooling processes without manual intervention.

Key Benefits

- Designed with world-leading technology and craftsmanship for reliability and safety

- Utilizes Siemens PLC and programmable controllers for integrated electrical, mechanical, and pneumatic systems

- Supports flexible packaging configurations (e.g., two, three, or four lines) with easy switching via rotating switch

- Incorporates worm gear reducer to eliminate vibration during in-feeding and film feeding

- Features a special sealer with Teflon coating for secure, non-stick sealing and PE conveyor for high abrasion resistance

- Includes automatic feeding fixtures tailored to bottle shapes and optional color coding for positioning with colorful materials

- Offers modular design for quick exchange when bottle shapes change and customizable conveyor in-feed directions

- Equipped with double wind engine for even heat distribution and enhanced package appearance

- Uses silicon rubber-covered rollers to extend conveyor lifespan, with material options based on customer requirements

- Provides frequency converter-controlled conveying speed for unrestricted regulation and strong wind cooling for instant post-shrink cooling

- Optional roller table at shrink tunnel exit to prevent product falls

SK-060CBS Fully Automatic Sleeve Shrinking Machine Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Sealing Method | Special sealer with Teflon coating |

| Conveyor Material | PE (high anti-abrasion, high strength) |

| Heat Distribution | Double wind engine |

| Cooling System | Strong wind cooling |

| Optional Features | Color coding system, roller table |

Frequently Asked Questions

Common questions about SK-060CBS Fully Automatic Sleeve Shrinking Machine and our services.

Q:What is the SK-060CBS sleeve packing machine designed for?

Q:What control system does the SK-060CBS use?

Q:Can the SK-060CBS handle different packaging configurations?

Q:What are the key features for durability and performance?

Related Products

SK-060ABS Automatic Sleeve Type Shrink Bundling Machine

SK-060BBS Fully Automatic Sleeve Shrinking Machine

SK-060EBS Fully Automatic Shrink Bundling Machine

SK-075C Automatic Sleeve Shrinking Machine

Ready to Upgrade Your Production Line?

Get a customized quote for SK-060CBS Fully Automatic Sleeve Shrinking Machine and discover how it can optimize your operations.