Case Study: 300% Efficiency Gain for Chile's Top Copper Producer

Chile is the beating heart of the global copper industry, supplying nearly 28% of the world's copper. For our client, a leading copper service center in Santiago, maintaining that competitive edge means more than just mining—it means delivering pristine, high-value copper strips to customers worldwide.

However, as their slitting capacity expanded to meet global demand for EV battery components, their packaging line became a critical bottleneck.

This case study details how we partnered with them to deploy a Fully Automated Copper Coil Packing Line, achieving a 300% increase in throughput while solving their most persistent quality issue: surface oxidation.

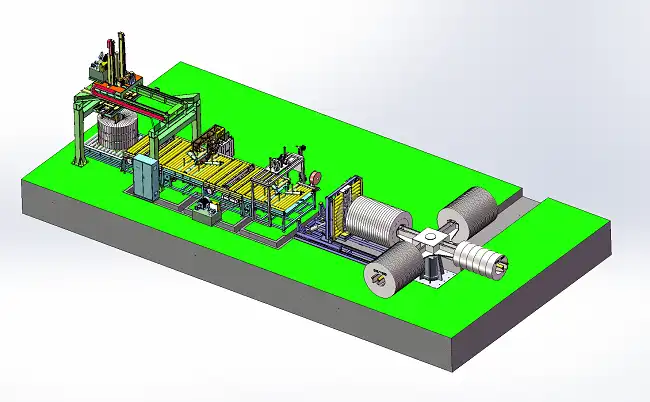

Figure 1: The completed automated line in the Santiago facility.

Figure 1: The completed automated line in the Santiago facility.

The Challenge: The "Manual" Bottleneck

Before the upgrade, the client's operation relied on manual labor for the final 50 meters of their production line.

- The Bottleneck: The high-speed slitter could produce 10 coils every few minutes, but the packaging team (4 operators) could only wrap and stack 1 coil every 5 minutes. This forced the slitter to stop frequently, killing overall OEE (Overall Equipment Effectiveness).

- The Quality Cost: Copper is incredibly sensitive. Manual handling with forklifts and chains caused minor dents on the outer layers. Worse, inconsistent manual wrapping allowed moisture ingress during sea freight to Asia, leading to "brown stain" oxidation claims.

- Safety: Operators were manually flipping 500kg coils, a recipe for back injuries and pinch-point accidents.

"We were producing world-class copper, but our packaging made it look second-rate. We needed a solution that treated our product with the same precision as our rolling mills." — Operations Director

The Solution: A "No-Touch" Automated System

We proposed a turnkey Automatic Copper Coil Packing Line customized for soft, non-ferrous metals. The core philosophy was simple: No metal-to-metal contact.

Phase 1: Intelligent Buffering & Handling

To decouple the slitting line from the packing process, we installed a 4-Arm Turnstile with rubber-coated cantilevers.

- Result: The slitter can now unload a full master coil's worth of slit strips onto the turnstile and immediately start the next run, while the packing line processes the buffer autonomously.

- Down-Ending: A hydraulic down-ender with Nylon pads gently tilts the coils from "Eye-to-Wall" to "Eye-to-Sky" without scratching the edges.

Figure 2: The FPC-Series Wrapper applying the dual-layer protection.

Figure 2: The FPC-Series Wrapper applying the dual-layer protection.

Phase 2: The "Anti-Oxidation" Wrapping Protocol

The most critical upgrade was the wrapping station. We implemented our FPC-300 Copper Coil Wrapper with a dual-shuttle system.

- Inner Layer: Crepe Paper. This absorbs any residual rolling oil and cushions the coil layers.

- Outer Layer: VCI Stretch Film. This creates a hermetic seal against moisture and salt air.

- Tension Control: The machine uses active tensioning to ensure a tight wrap without deforming the soft copper ID (Inner Diameter).

Phase 3: Vacuum Stacking (The Game Changer)

In the old manual process, operators used magnetic lifters (impossible for copper) or mechanical clamps (risk of edge damage).

We installed a Vacuum Suction Stacking System.

- Precision: The vacuum head picks up the wrapped coil from the top face.

- Safety: It places the coil onto the pallet with ±1mm accuracy.

- Zero Damage: Since there are no mechanical jaws, the delicate edges of the copper strip are never touched.

System Layout Diagram

Hover over points to see station details. This is a simplified layout representation.

Implementation & Results

The installation was completed in just 10 days during a planned plant shutdown.

Key Performance Indicators (KPIs) Post-Installation:

- Throughput: Increased from 12 coils/hour to 45 coils/hour (nearly 400% increase).

- Labor: Reduced from 4 operators per shift to 1 system monitor. The displaced workers were upskilled to operate the line.

- Claims: Customer claims regarding oxidation and edge damage dropped to Zero in the first 12 months.

- ROI: The project achieved full Return on Investment in 8 months, primarily driven by labor savings and the elimination of scrap.

Figure 3: The complete line, showing the flow from wrapping to the palletizing station.

Figure 3: The complete line, showing the flow from wrapping to the palletizing station.

Conclusion

This project proves that for high-value materials like copper, automation is not just about speed—it's about preservation of value. By automating the packing process, our client in Chile has secured their reputation as a premium supplier in the global market.

Facing similar challenges? Whether you are processing steel, copper, or aluminum, we have the engineering expertise to build your solution.

- View Our Copper Packing Solutions

- Read More: Copper vs. Steel Packing Guide

- Contact Us for a Consultation