Tap thumbnails to view different images

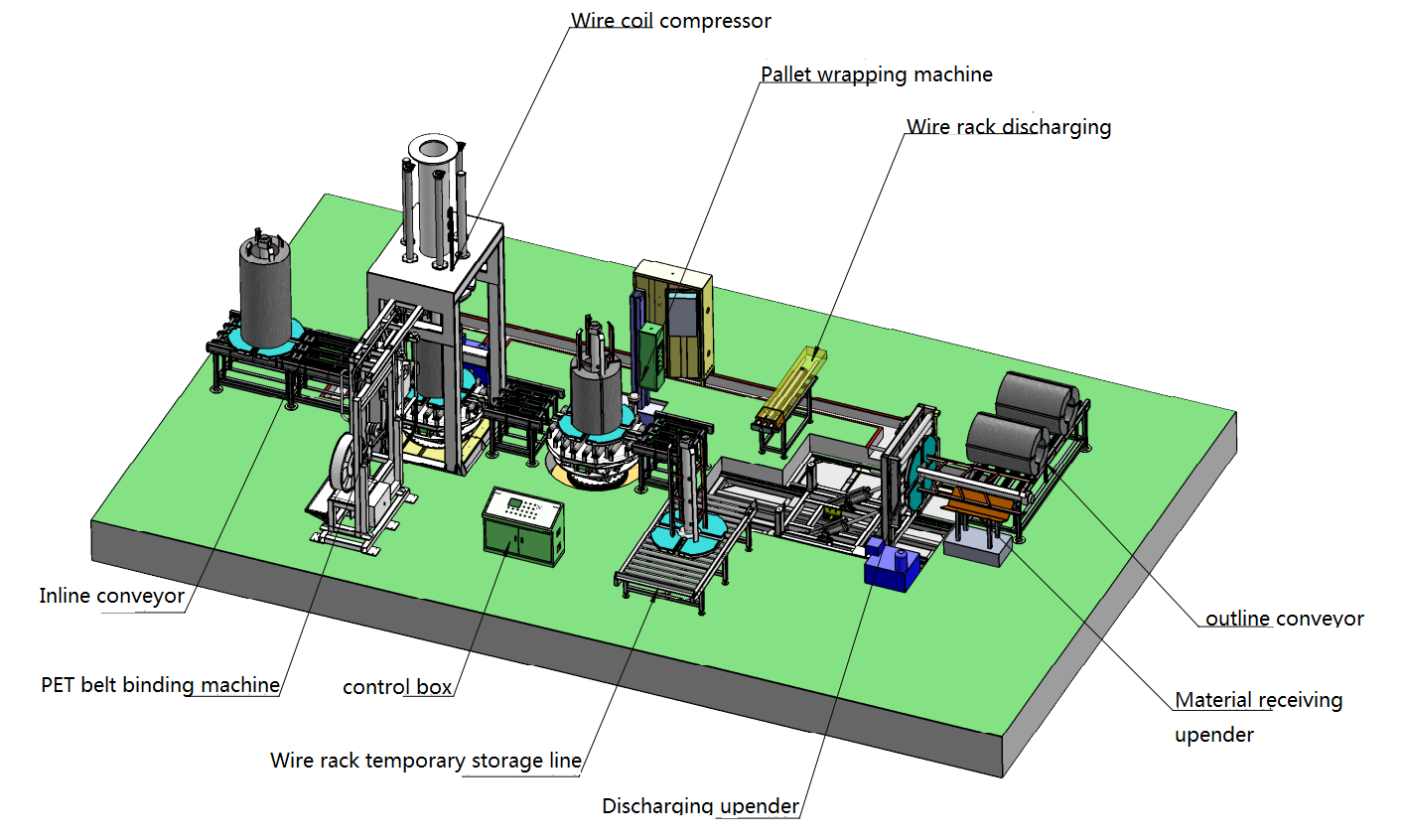

Automatic Wire Coil Compacting and Strapping Line

Boost packaging efficiency with our automatic wire coil compressing and strapping line. Handles up to 8 coils per hour, reduces labor costs, and ensures safe, compact packaging for wire coils.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

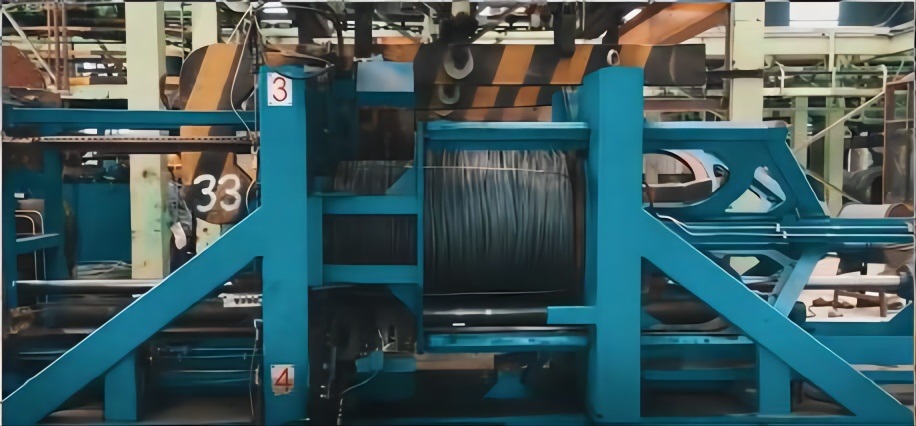

This automatic wire coil compressing and strapping packing line provides a complete solution for connecting compressing with a drawing machine to handle baskets, efficiently gathering wire coils. The system processes wire coils along with their baskets on a table, where the compactor compacts the coils on spools, with adjustable settings via inverters to accommodate various materials.

Designed for handling up to 8 coils per hour, each with 4 radial straps, this line operates 24/7 to maximize productivity. The automatic strapping machine and compactor feature HDPE-protected contact zones to prevent damage to wire coils, ensuring safe and reliable packaging.

Ideal for improving wire coil packaging, this equipment meets handling and stacking requirements, enhances packaging efficiency, minimizes space usage, and reduces labor costs in wire handling operations.

Key Benefits

- Automatic compressing and strapping for wire coils with baskets

- Handles up to 8 coils per hour with 4 radial straps each

- HDPE-protected contact zones to prevent coil damage

- Adjustable settings via inverters for material accommodation

- Designed for 24/7 operation to maximize productivity

- Reduces labor costs and improves packaging efficiency

Technical Specifications

| Specification | Value |

|---|---|

| Material | GI wire coil |

| The Coil Is Positioned On | Basket |

| Min Diameter Of The Wire | 2.50 mm |

| Height Of The Wire Coil Before Compacting | 1200 mm |

| Height Of The Wire Coils After Compacting | 800 mm |

| Max Weight Of The Wire Coil | 2000 Kg |

| Temperature Of The Material | Normal |

| Dimensions Of The Basket | 1200 Dia base mm |

| Required Compacting Force | 2-3 Ton |

| Number Of The Straps Per Coil | 4 Nos |

| Strap Width | 19 mm |

| Strap Thickness | 1.00 / 1.27 mm |

| Type Of Strap | Polyester |

| Strap Quality | Smooth / High quality polyester strap |

Frequently Asked Questions

Common questions about Automatic Wire Coil Compacting and Strapping Line and our services.

Q:What is the capacity of this automatic wire coil packing line?

Q:How does the system protect wire coils during compressing and strapping?

Q:Can this equipment operate continuously?

Q:What types of wire coils can this line handle?

Related Products

Automatic Wire Coil Compacting and Strapping System

Automatic Wire Coil Compressing and Strapping Packing Line

Automatic Steel Wire Coil Compactor and Strapping Machine

Automatic Wire Rod Compacting and Strapping Machine

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Wire Coil Compacting and Strapping Line and discover how it can optimize your operations.