Tap thumbnails to view different images

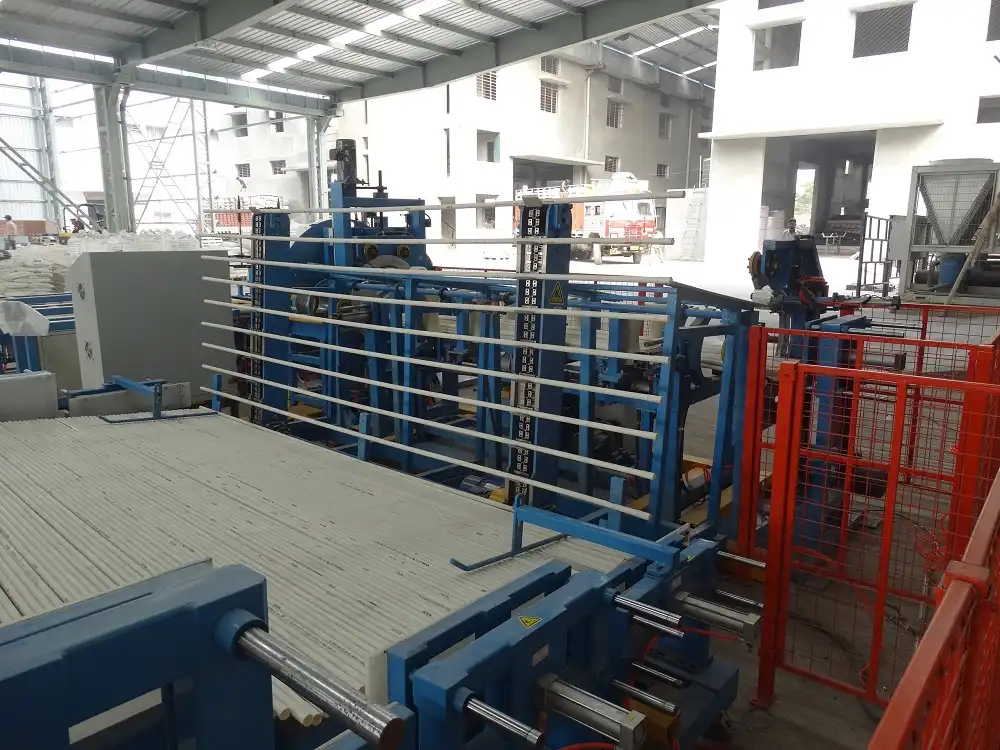

Automatic Pipe Capping Machine

High-speed automatic pipe capping machine for PPR pipes, handling diameters 20-32mm. Features PLC control, low failure rate, and customizable options for efficient pipe production lines.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The Automatic Pipe Capping Machine is designed for efficient and reliable capping of PPR pipes in industrial production lines. It automates the capping process with high speed and precision, reducing manual labor and enhancing productivity. Suitable for pipe diameters from 20mm to 32mm, this machine offers customizable specifications to meet specific production needs. It integrates advanced control systems including HMI and PLC, ensuring smooth operation and easy monitoring. Ideal for indoor environments, it supports various pipe lengths and cap designs, making it a versatile solution for pipe manufacturing facilities.

Key Benefits

- High-speed capping with a cycle time of less than 2 seconds

- Low failure rate of less than 1 in 50,000 caps

- Customizable for different pipe diameters and cap designs

- Advanced control system with HMI, PLC, and photoelectric sensors

- Energy-efficient operation with less than 300W power consumption

Automatic Pipe Capping Machine Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Equipment Name | Automatic Pipe Capping Machine |

| Scope | Pipe production line |

| Environment | Indoor |

| Temperature Range | -20°C to 45°C |

| Altitude Range | 0-3000m |

| Electricity Consumption | Less than 300W |

| Air Source | 0.5 MPa |

| Gas Consumption | Less than 1.0 m³/h |

| Pipe Material | National standard size, length 3m or 4m, length deviation ±10mm |

| Tube Cap Requirements | Injection molding flying edge less than 4mm, roundness not required |

| Size | 5500mm * 1200mm * 1100mm (length * width * height) |

| Color | Light yellow, other colors customizable |

| Installation | Turnkey project provided |

| Block Failure Rate | Less than 1 in 50,000 |

| Failure Detection | Optional (additional cost) |

| Automatic Counting Subcontracting | Available |

| Vibration Plate | Designed according to customer-provided pipe cap |

| Tube Cap Detection | Photoelectric switch |

| Pipe Testing | Photoelectric switch |

| Air Source Treatment | Automatic drainage, double pressure adjustment, separate adjustment of cap strength |

| Communications | Industrial Ethernet, speed 10M |

Frequently Asked Questions

Common questions about Automatic Pipe Capping Machine and our services.

Q:What pipe diameters does this automatic capping machine support?

Q:What is the capping speed of this machine?

Q:Can this machine be customized for different production needs?

Q:What control systems are used in this machine?

Q:Is installation support provided with this machine?

Related Products

Automatic Plastic Pipe Bundle Making and Bagging Machine

Automatic Pipe Bundle Making and Banding Packing Machine

Automatic Pipe Online Bundling and Banding Machine

JL-CX6000 Automatic Pipe Bundling and Bagging Line

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Pipe Capping Machine and discover how it can optimize your operations.