The Ultimate Guide to Hose & Pipe Coil Packaging: From Extrusion to Retail

In the competitive world of plastic extrusion, the production line doesn't end at the cutter. For manufacturers of HDPE pipes, PEX tubing, Corrugated Hoses, and Drip Irrigation lines, the final packaging stage is critical. A messy, loose coil suggests a low-quality product, while a tight, perfectly wrapped coil screams "professional grade."

Unlike steel or copper, plastic coils are lightweight, springy, and prone to "telescoping" (unraveling from the center). Manual coiling and wrapping are slow, labor-intensive, and often result in inconsistent package sizes that are a nightmare to stack on pallets.

This guide explores the specialized automation technologies designed to tame the "unruly coil," ensuring your product arrives at the construction site or retail shelf in pristine condition.

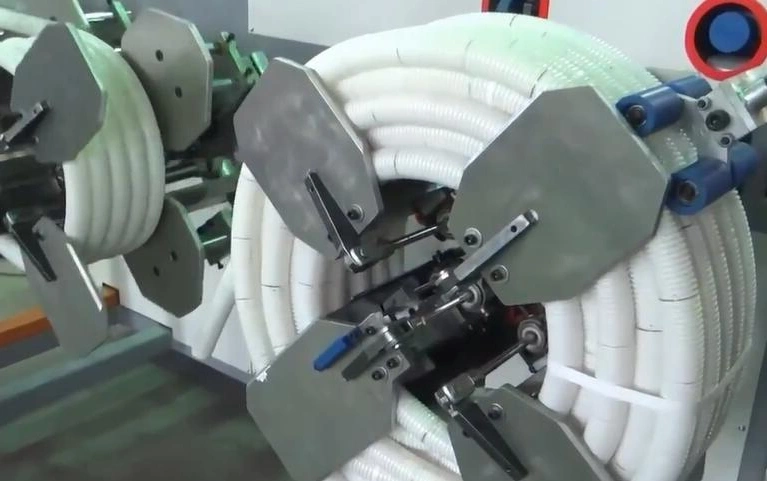

Figure 1: A dual-station automatic coiler integrated directly with a high-speed corrugated pipe extrusion line.

Figure 1: A dual-station automatic coiler integrated directly with a high-speed corrugated pipe extrusion line.

1. The Challenge: Taming the "Springy" Coil

Plastic pipes and hoses have "memory." They want to return to a straight line. When coiled, they store potential energy, acting like a giant spring.

Manual vs. Automated Packing

| Feature | Manual / Semi-Auto | Fully Automated Line | | :--- | :--- | :--- | | Coiling Speed | Limited by operator fatigue (approx. 2-3 min/coil) | Synchronized with extruder (up to 300m/min) | | Consistency | Variable coil ID/OD, often loose | Precise, programmable dimensions | | Labor | 2-3 operators per line (coiling + strapping + wrapping) | 1 operator monitoring 3-4 lines | | Packaging Material | High waste (manual film wrapping) | Optimized overlap, 30% material saving |

The Solution: An integrated Automatic Coiler & Wrapper that captures the pipe directly from the extruder, winds it under controlled tension, straps it, and wraps it—all without human hands.

2. Phase I: Precision Coiling (The Foundation)

A good package starts with a good coil. If the winding is messy, no amount of wrapping will fix it.

Automatic Coilers (Vertical vs. Horizontal)

- Vertical Coilers (For Flexible Pipes): Ideal for small diameter pipes (16mm - 32mm) like PEX or Al-PEX. The coiling plates spin vertically. Gravity helps the finished coil drop onto a conveyor.

- Horizontal Coilers (For Rigid Pipes): Used for larger HDPE pipes (up to 110mm+). The winding force is higher to bend the stiff pipe.

Key Technology: The Accumulator

To allow for continuous extrusion while the coiler stops to cut and eject a coil, an Accumulator (Dancer) is essential. It buffers the incoming pipe, maintaining constant line tension so the extruder never has to slow down.

Figure 2: A neat, strapped coil produced by an automatic winder.

Figure 2: A neat, strapped coil produced by an automatic winder.

3. Phase II: Strapping – Locking in the Energy

Once the coil is wound, it must be secured immediately to prevent it from springing open ("exploding").

PP Strapping Technology

For plastic pipes, we use Polypropylene (PP) Strap. It is soft enough not to cut into the pipe but strong enough to hold the tension.

- Auto-Strapping: The machine indexes the coil and applies 2, 3, or 4 straps radially.

- Tension Control: Critical for corrugated hoses. Too tight, and you crush the ribs. Too loose, and the coil expands. Our systems use "Soft Tension" modes specifically for crushable products.

4. Phase III: Orbital Wrapping – The Retail Finish

For products sold in retail stores (like garden hoses) or stored outdoors (like irrigation pipes), wrapping is mandatory. It protects against UV rays, dirt, and abrasion.

The FPH Series: High-Speed Vertical Wrapping

The FPH-300 Hose Coil Wrapper is the industry standard for this task.

- Speed: It can wrap a standard coil in 15-20 seconds.

- Eye-to-Sky Operation: The coil rests flat on the conveyor. A rotating ring passes the film through the eye of the coil.

- Materials:

- Stretch Film: Clear or colored (for branding).

- Woven Belt: For heavy-duty protection.

- Paper: For a premium, eco-friendly look.

Branding Opportunity

Using printed stretch film with your logo is the most cost-effective marketing tool. Every meter of pipe carries your brand identity from the factory to the end-user.

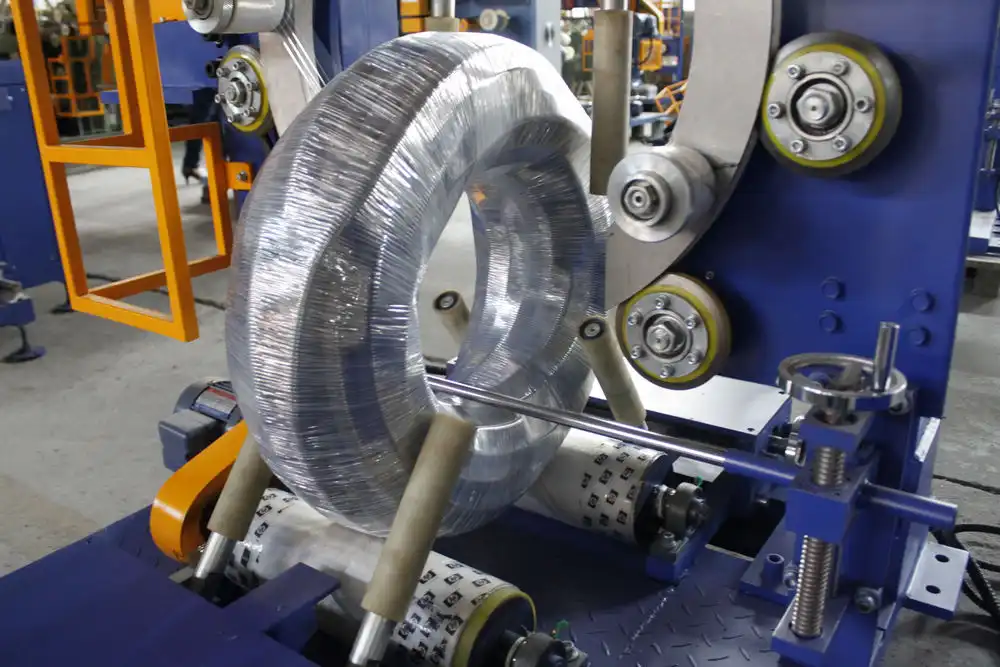

Figure 3: The FPH-300N applying a branded stretch film to a flexible hose coil.

Figure 3: The FPH-300N applying a branded stretch film to a flexible hose coil.

5. Phase IV: Shrink Wrapping – The Alternative

For small consumer coils (e.g., 10m - 25m DIY packs), Shrink Wrapping offers a "Crystal Clear" finish often preferred by big-box retailers.

- Process: The coil is sealed in a POF (Polyolefin) bag and passed through a heat tunnel.

- Result: A tight, glossy package that looks great on a shelf and prevents pilferage of fittings/accessories often packed inside the coil.

6. Conclusion: Automate to Compete

In the low-margin, high-volume world of plastic pipe extrusion, pennies count. An automated packing line reduces your labor cost per coil by over 80% while significantly upgrading your product presentation.

Don't let your packaging be the bottleneck.

- View Hose & Pipe Coilers

- Explore Coil Wrapping Machines

- Request a Layout Drawing for your extrusion plant.