Tap thumbnails to view different images

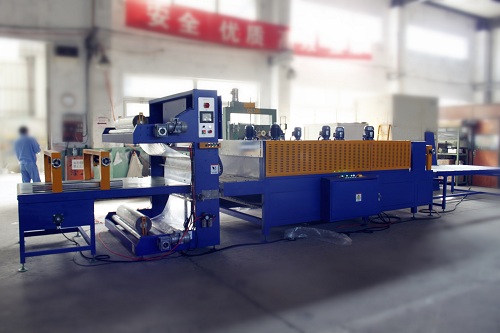

Panel Shrinking & Packing Machine

Discover high-efficiency automatic EPS panel shrinking machines for secure packaging. Ideal for EPS, XPS, glass foam, and insulation panels, reducing labor costs with customizable solutions.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

Fhope provides a series of panel packing machines, including panel shrink bundling machines, panel shrink wrap machines, and panel handling and packaging lines. These machines are designed by expert engineers to deliver sealed and perfect packaging, protecting products during storage and transportation. They are easy to operate, even for non-skilled operators, and offer high efficiency with a reasonable price for fast investment return. Our experienced team assists with custom projects to meet specific needs.

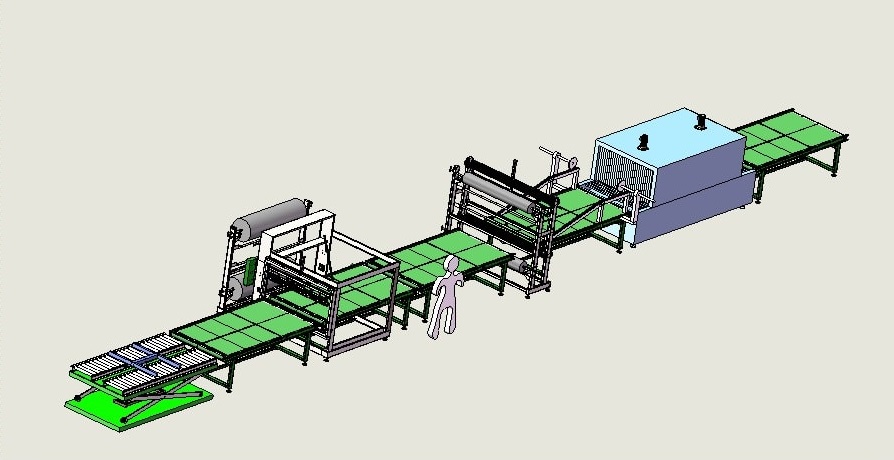

This automatic panel bundle shrink packing machine is designed for various panel sizes and film requirements, with options to connect to production systems via conveyors and handling systems. It automates bundling, strapping, and labeling, significantly reducing labor costs through flexible design.

The EPS bag packing machine is designed for sealed panel bagging without heating, suitable for low heat-resistant panels. It features a bag-forming device and uses servo motors for high-speed, efficient packaging, with components from reputable brands for reliability.

The automatic panel bag shrink wrap machine combines bag forming and heat shrinking for sealed packaging, offering high efficiency and cost savings. It includes features like photo-electric induction, adjustable settings, and compatibility with various films like PE, POF, and PVC.

Key Benefits

- Automated panel shrink bundling for reduced labor costs

- Customizable solutions for EPS, XPS, glass foam, and insulation panels

- Easy operation by non-skilled operators with high efficiency

- Sealed packaging to protect products in storage and transportation

- Servo motor-driven components for high-speed and efficient performance

- Compatible with PE, POF, and PVC films for versatile applications

- Adjustable settings for different panel sizes and packaging requirements

- Integration with production lines for full automation

Technical Specifications

| Specification | Value |

|---|---|

| Air Supply | >5Bar to 6-8 kgf/cm² |

| Packing Object Length | 300-1000mm |

| Packing Object Height | 180-500mm |

| Shrinking Tunnel Length | 4000mm |

| Temperature Range | 100℃-220℃ |

| Packing Materials | PE, POF, PVC film with reserve pore |

| Structure Material | Carbon Steel |

Frequently Asked Questions

Common questions about Panel Shrinking & Packing Machine and our services.

Q:What types of panels can this machine handle?

Q:Is the machine easy to operate for non-skilled workers?

Q:Can the machine be integrated into existing production lines?

Q:What are the power requirements for this machine?

Related Products

Industrial Door Shrink Wrap Machine

FPSH-B100 Automated Board & Profile Shrink Wrapping System

Industrial Pallet Shrink Wrap Machine with Heat Tunnel

Industrial Sofa Shrink Wrap Machine

Ready to Upgrade Your Production Line?

Get a customized quote for Panel Shrinking & Packing Machine and discover how it can optimize your operations.