Tap thumbnails to view different images

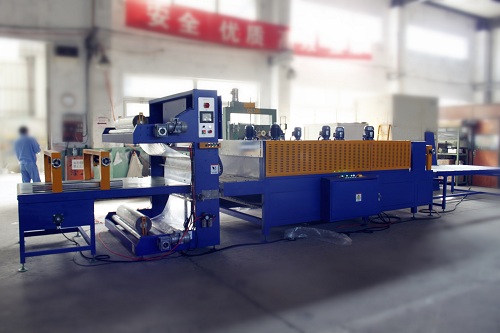

FPSH-B100 Automated Board & Profile Shrink Wrapping System

Discover the FPSH-B100 automatic board shrink wrapping machine. Features PLC control, adjustable sealing, and high-speed shrinking for profiles, boards, and doors. Save labor and material costs.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

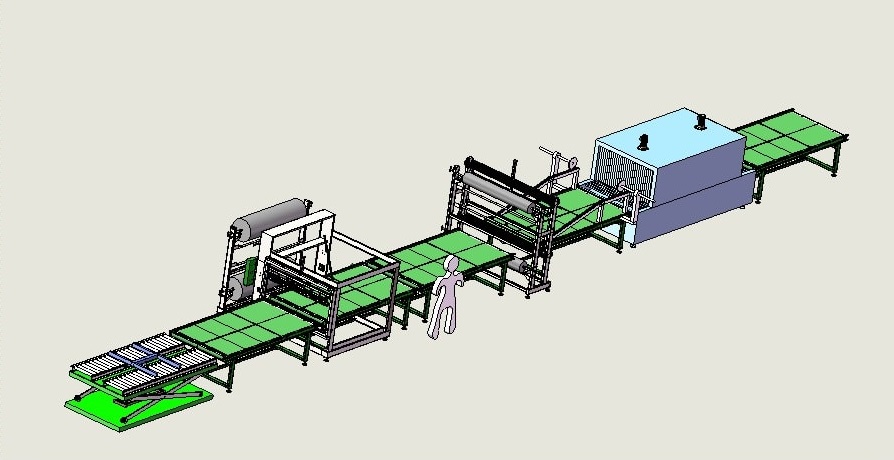

The FPSH-B100 is an automatic shrinking machine designed for packaging profiles, boards, windows, doors, and similar items. It offers one-side sealing and full-side packaging, delivering high efficiency and a neat finish to reduce labor and material costs. This machine integrates seamlessly with automatic production lines, supporting various feed-in modes and packaging materials.

Key Benefits

- Automatic shrink wrapping with integration into production lines for feeding, sealing, and material recovery

- Full-side shrinking packaging for complete coverage and protection

- Photo-electric induction for precise product positioning

- Dual feed-in modes: automatic and manual for flexible operation

- Uses PE or POF film on rolls with automatic sealing of three sides

- Constant temperature heat sealing and cutting system compatible with PE, PVC, and POF films

- Adjustable sealing width to accommodate different product sizes

- Adjustable front feed-in speed with a worktable for high automation

- High-speed hot air circulating shrink tunnel for efficient shrinking

- Permanently heated seal bar with easy-exchangeable blade, PLC-controlled temperature

Technical Specifications

| Specification | Value |

|---|---|

| Model | FPSH-B100 |

| Structure Material | Carbon Steel |

| Packing Objects Length | 800-4000 mm |

| Packing Objects Height | 20-300 mm |

| Height of Working Table | Approx. 800 mm |

| Packaging Type | Full Packaging |

| Packing Material | PE/POF/PVC film with reserve pore |

| Air Supply | 6-8 kgf/cm² |

| Shrinking Part Length | 2000 mm |

| Shrinking Tunnel Length | 4000 mm |

| Shrinking Side Dimensions | W 1200 mm x 300 mm |

| Calorific Units | 4 PCS |

| Cooling Fans | 1 Group |

| Drive Part | Frequency Control Motor |

| Conveyor Speed ( Shrinking Part) | Approx. 6 m/min |

| Temperature Range | 100°C-220°C |

Frequently Asked Questions

Common questions about FPSH-B100 Automated Board & Profile Shrink Wrapping System and our services.

Q:What types of products can the FPSH-B100 machine package?

Q:What packaging materials are compatible with this machine?

Q:How does the machine ensure precise product positioning?

Q:Can the FPSH-B100 be integrated into an automatic production line?

Related Products

Industrial Door Shrink Wrap Machine

Panel Shrinking & Packing Machine

Industrial Pallet Shrink Wrap Machine with Heat Tunnel

Industrial Sofa Shrink Wrap Machine

Ready to Upgrade Your Production Line?

Get a customized quote for FPSH-B100 Automated Board & Profile Shrink Wrapping System and discover how it can optimize your operations.