Tap thumbnails to view different images

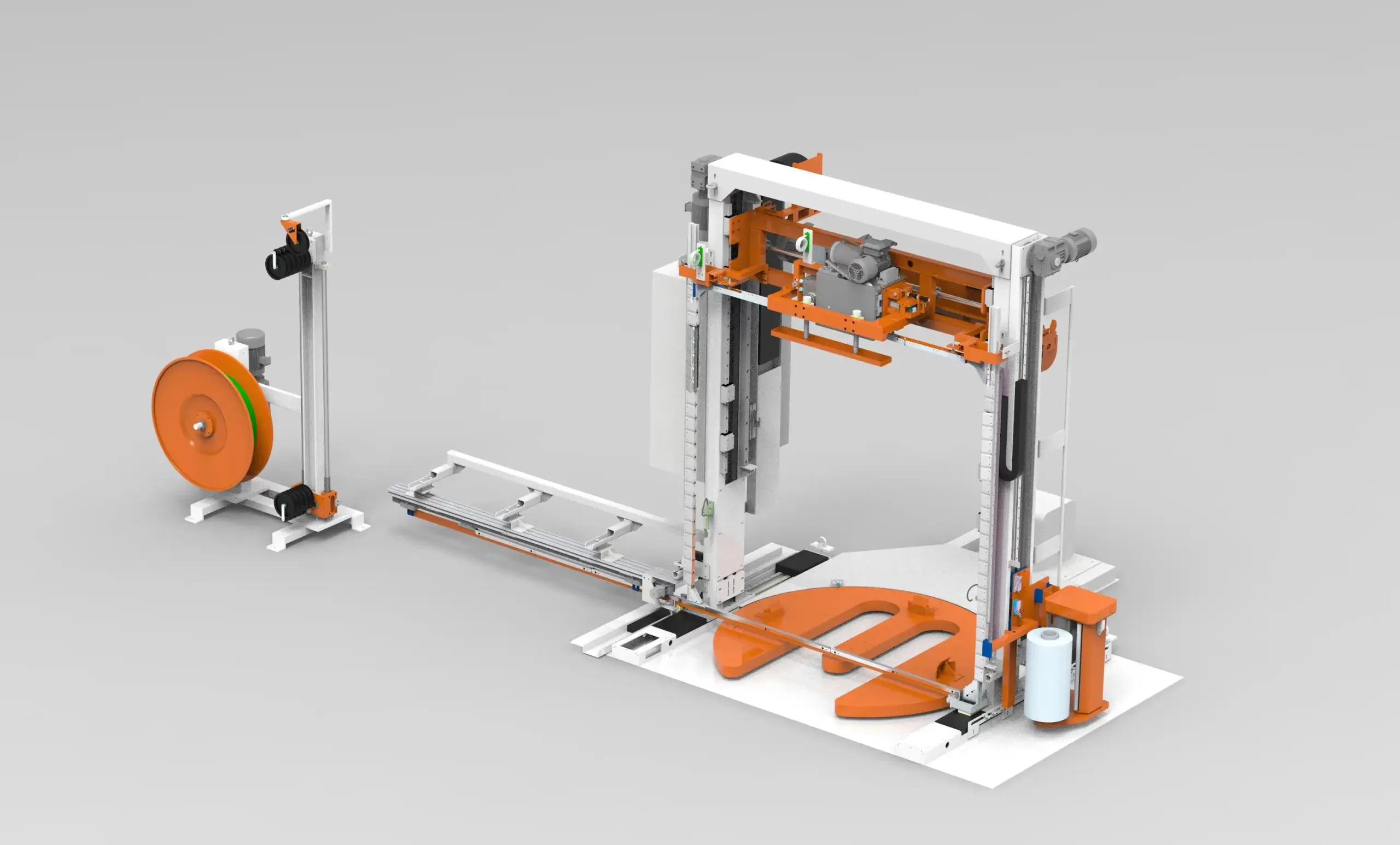

Integrated Pallet Wrapping and Strapping Machine

Discover our Integrated Pallet Wrapping and Strapping Machine, designed to automate packaging with adjustable strapping, a consolidated station, and high load capacity for enhanced efficiency.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

This document outlines the technical specifications and operational features of the Integrated Pallet Wrapping and Strapping Machine, also commonly referred to as a Combined Pallet Wrapper and Strapper. The system is engineered to automate and combine pallet stretch wrapping and strapping processes, aiming to enhance end-of-line packaging efficiency and load security within a consolidated machine footprint.

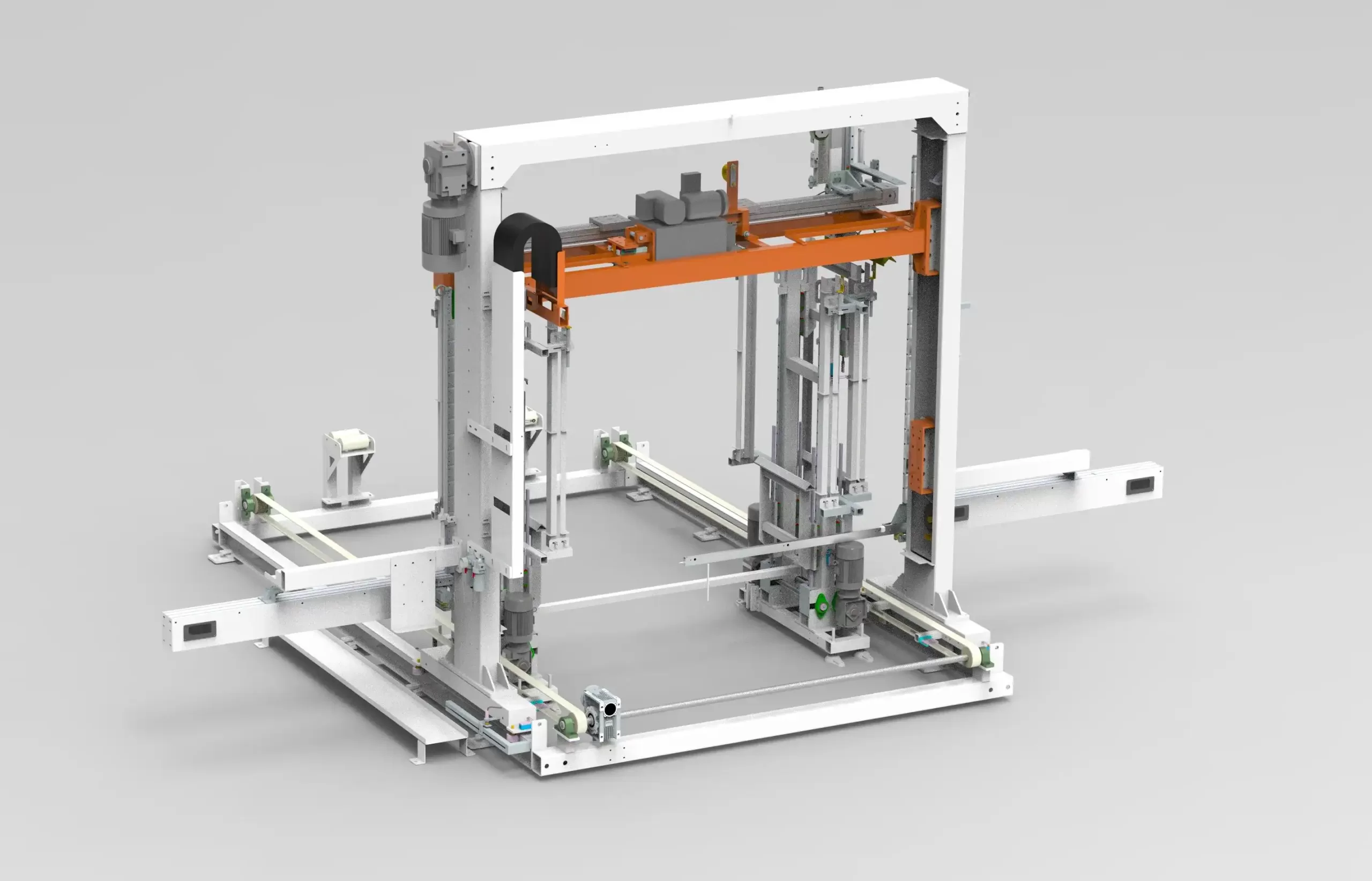

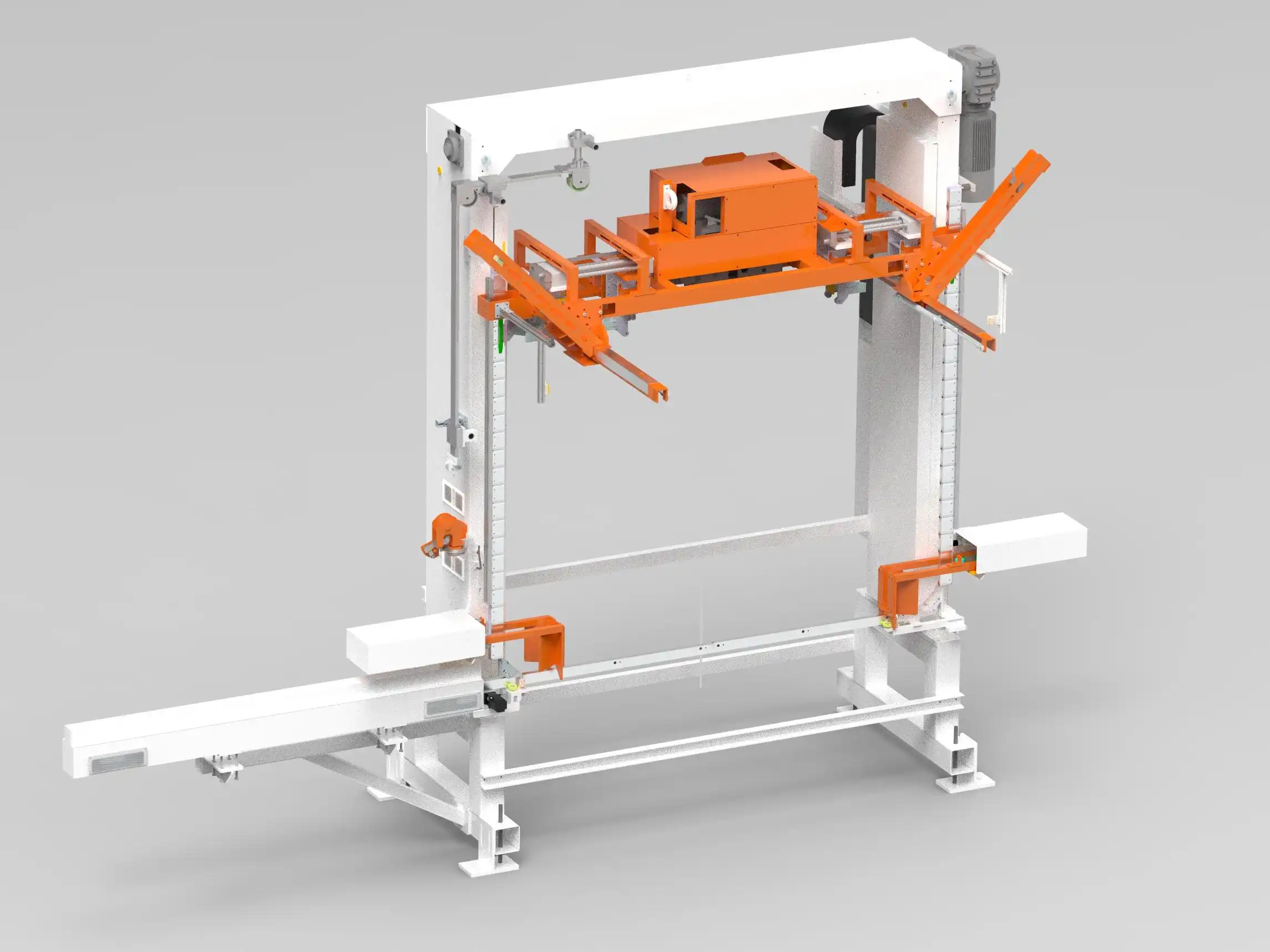

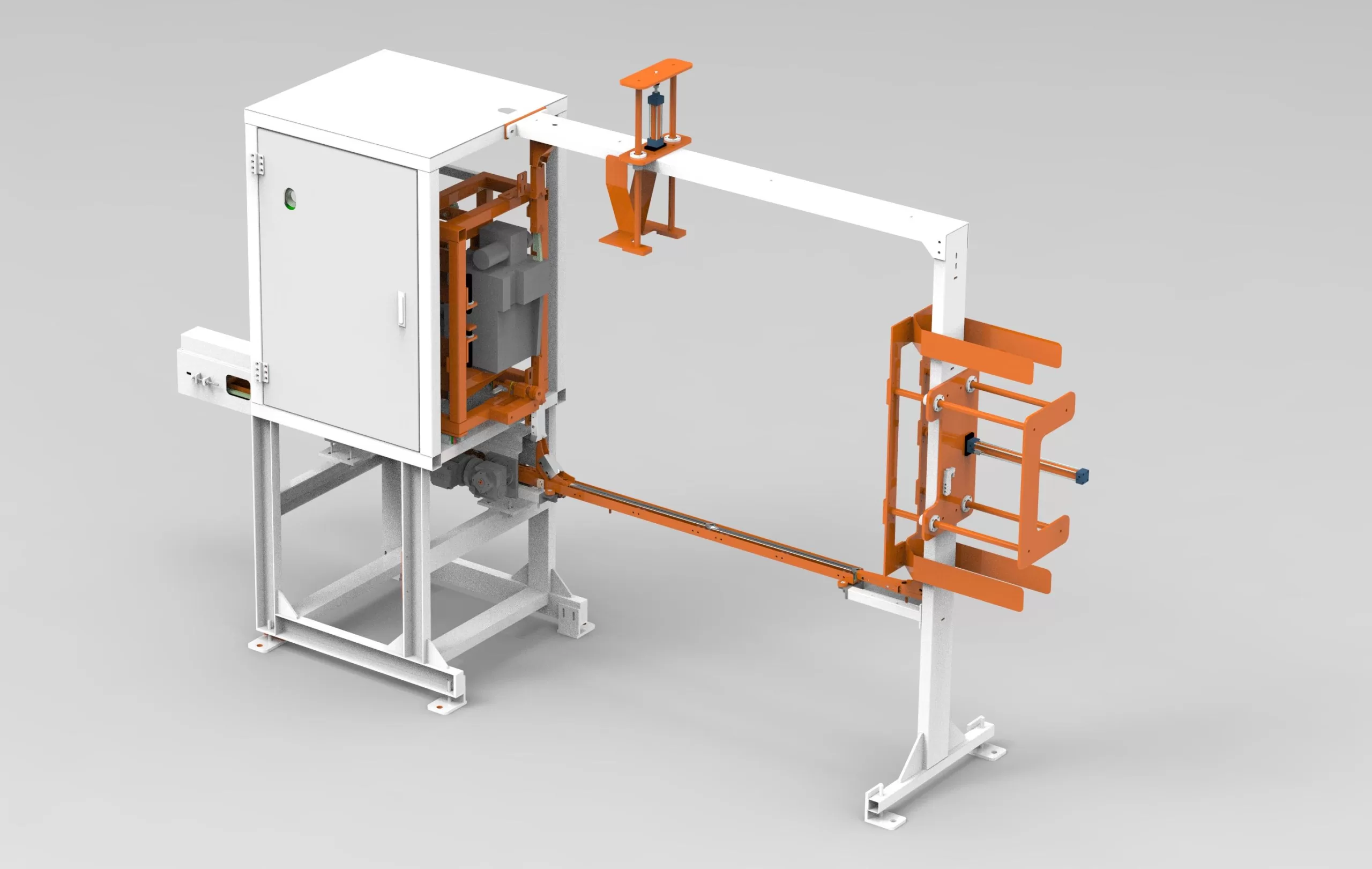

The Combined Pallet Wrapper and Strapper incorporates key features to facilitate its intended functions, including adjustable height strapping, a consolidated station, and a floating head for tension distribution.

This Integrated Pallet Wrapping and Strapping Machine is designed for applications requiring consistent and secure unitization of pallet loads for storage or distribution.

Key Benefits

- Adjustable Height Strapping Mechanism for flexible cargo handling

- Consolidated Wrapping and Strapping Station to save floor space

- Floating Head for uniform tension distribution and load integrity

- Mechanical Strap Dispensing Unit for reliable operation

- Human-Machine Interface (HMI) for easy parameter adjustments

Technical Specifications

| Specification | Value |

|---|---|

| Maximum Packaging Height | 1800mm |

| Maximum Packaging Length | 1300mm |

| Turntable Height | 80mm |

| Strap Joint Sealing Method | Friction Weld |

| Strapping Tension Range | 50-5000N (Adjustable) |

| Seal Length | 20mm |

| Single Strap Cycle Time | Approximately 15 seconds |

| Electrical Supply Requirements | 380V / 50Hz |

| Nominal Power Consumption | 5KW |

Frequently Asked Questions

Common questions about Integrated Pallet Wrapping and Strapping Machine and our services.

Q:What is the main benefit of the Integrated Pallet Wrapping and Strapping Machine?

Q:What types of straps are compatible with this machine?

Q:How does the adjustable height strapping feature work?

Related Products

Automatic Turntable Pallet Strapping Machine

Vertical Pallet Strapping Machine

Automatic Battery Strapping Machine

Side Seal Pallet Strapping Machine

Ready to Upgrade Your Production Line?

Get a customized quote for Integrated Pallet Wrapping and Strapping Machine and discover how it can optimize your operations.