Tap thumbnails to view different images

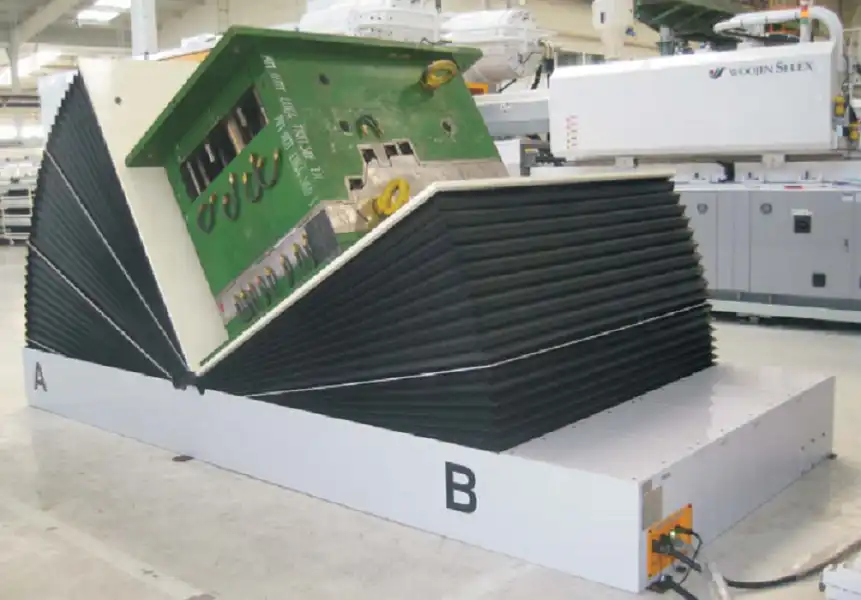

Industrial Mold Flipper Lift Table

Discover our Mold Flipper, Flipper Lift Table, and Mold Reverser designed to safely flip heavy molds, boost productivity, and reduce downtime. Ideal for automotive and manufacturing industries.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

Our Mold Flipper is engineered to streamline your operations by safely and efficiently flipping heavy molds, eliminating manual labor to enhance productivity and minimize downtime.

This versatile equipment is suitable for various industries, including automotive and consumer goods, offering robust construction and user-friendly operation.

It supports applications such as mold processing, assembly, and injection die handling, with customizable options to meet specific industrial needs.

Key Benefits

- High Load Capacity for handling molds of various sizes and weights

- Robust Construction with industrial-grade materials for maximum durability

- Safety-First Design with electrical and mechanical features to reduce workplace accidents

- Precision Handling for accurate mold positioning and flawless operation

- Easy Operation with a user-friendly interface and remote control for quick training

Industrial Mold Flipper Lift Table Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Type | FPFT-05, FPFT-10, FPFT-15, FPFT-20, FPFT-30, FPFT-40 |

| Length | 3010 mm to 5560 mm |

| Height | 300 mm to 500 mm |

| Max Load | 5 to 40 tons |

| Turning Degrees | 90 or 180 degrees |

| Safety Features | Mechanical and electric stop blocks, soft start and stop |

| Actuation | Double-acting hydraulic cylinders |

| Load/ Unload Method | Via forklift or crane |

Frequently Asked Questions

Common questions about Industrial Mold Flipper Lift Table and our services.

Q:What is the primary function of the Mold Flipper?

Q:What safety features are included?

Q:Can the Mold Flipper handle different mold sizes?

Q:How is the Mold Flipper operated?

Q:What industries is this equipment suitable for?

Related Products

FZ-H05 Industrial Hydraulic Tilter

FZ-H02 Heavy-Duty Industrial Roll Upender

10-Ton Hydraulic Coil Upender

Floor Base Hydraulic Upender

Ready to Upgrade Your Production Line?

Get a customized quote for Industrial Mold Flipper Lift Table and discover how it can optimize your operations.