Tap thumbnails to view different images

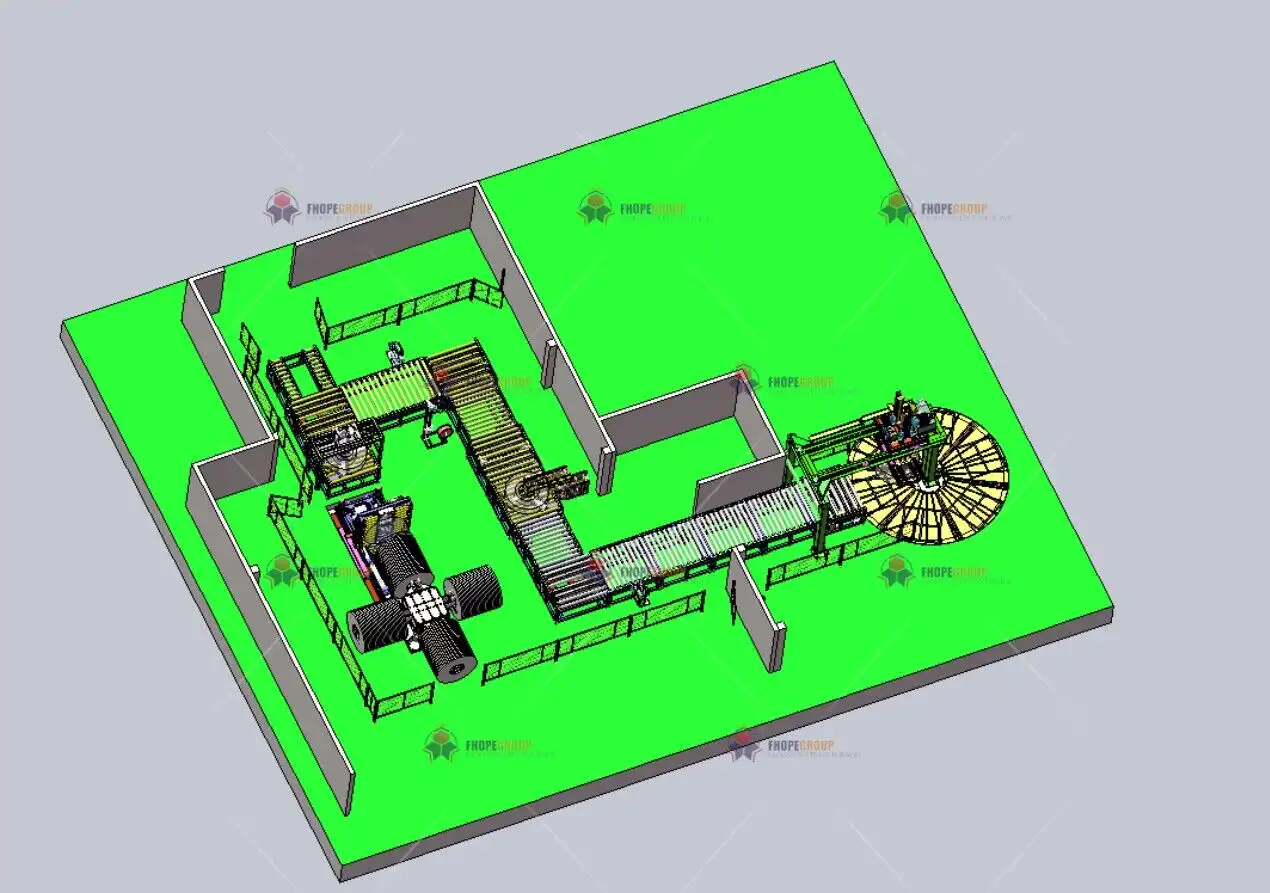

Automatic Slitting Coil Packaging Line with Turntable Stacker

FHOPE's Automatic Slit Coil Packaging System handles steel coils up to 5000 kg with components like PET strapping and woven belt wrapping. Features automation, 380V power, and integration with production systems.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The Automatic Slit Coil Packaging System is a comprehensive line designed for efficient packaging of steel coils, featuring a turntable stacker and multiple integrated components to streamline the process.

This system includes a cross arm, material flipping car, PET strapping machine, 90-degree transfer conveyors, horizontal transfer conveyor, inner diameter printing labeler, centering conveyor, woven belt wrapping machine, outer diameter printing labeler, centering pickup table, stacker, rotating stacking turntable, industrial computer, and control system.

Key Benefits

- Handles steel coils from 80 to 5000 kg with dimensions of OD 750-1400 mm, ID 508 mm, and width 17-400 mm

- Includes PET strapping machine for automatic angle adjustment and 3/4/6 strapping cycles

- Features woven belt wrapping machine with PP woven sheet for coil protection

- Equipped with stacker and turntable for up to 6000 kg per pallet and 6 stacking stations

- Integrated control system with industrial PC for automation and data sharing with production systems

Automatic Slitting Coil Packaging Line with Turntable Stacker Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Product Name | Automatic Slit Coil Packaging System | FHOPE |

| Cross Arm Maximum Loading | 10T per arm, 40T total |

| Cross Arm Length | 1500 mm |

| Coil Downender Minimum Width | 15 mm |

| Coil Downender Cycle Time | 20-30 seconds |

| Coil Downender Table Length | More than 1600 mm |

| P E T Strapping Material | PET, thickness 0.80 mm, width 16 mm |

| P E T Strapping Capacity | Approximately 15 seconds per cycle |

| Woven Belt Wrapping Material I D | 55 mm |

| Woven Belt Wrapping Material O D | 100-450 mm |

| Woven Belt Wrapping Material Width | 90-100 mm |

| Stacker Maximum Stacking Height | 1000 mm (including pallet height) |

| Stacker Maximum Stacking Weight | 6000 kg per pallet |

| Stacker Maximum Single Coil Weight | 4000 kg |

| Stacking Turntable Stations | 6 stations |

Frequently Asked Questions

Common questions about Automatic Slitting Coil Packaging Line with Turntable Stacker and our services.

Q:What is the weight range of steel coils this system can handle?

Q:What type of strapping does the PET strapping machine use?

Q:How does the control system integrate with production systems?

Related Products

Slit Coil Handling and Packaging Line

Economic Vertical Steel Slitting Coil Packaging Line

Automatic Slit Coil Packaging System

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Slitting Coil Packaging Line with Turntable Stacker and discover how it can optimize your operations.