Tap thumbnails to view different images

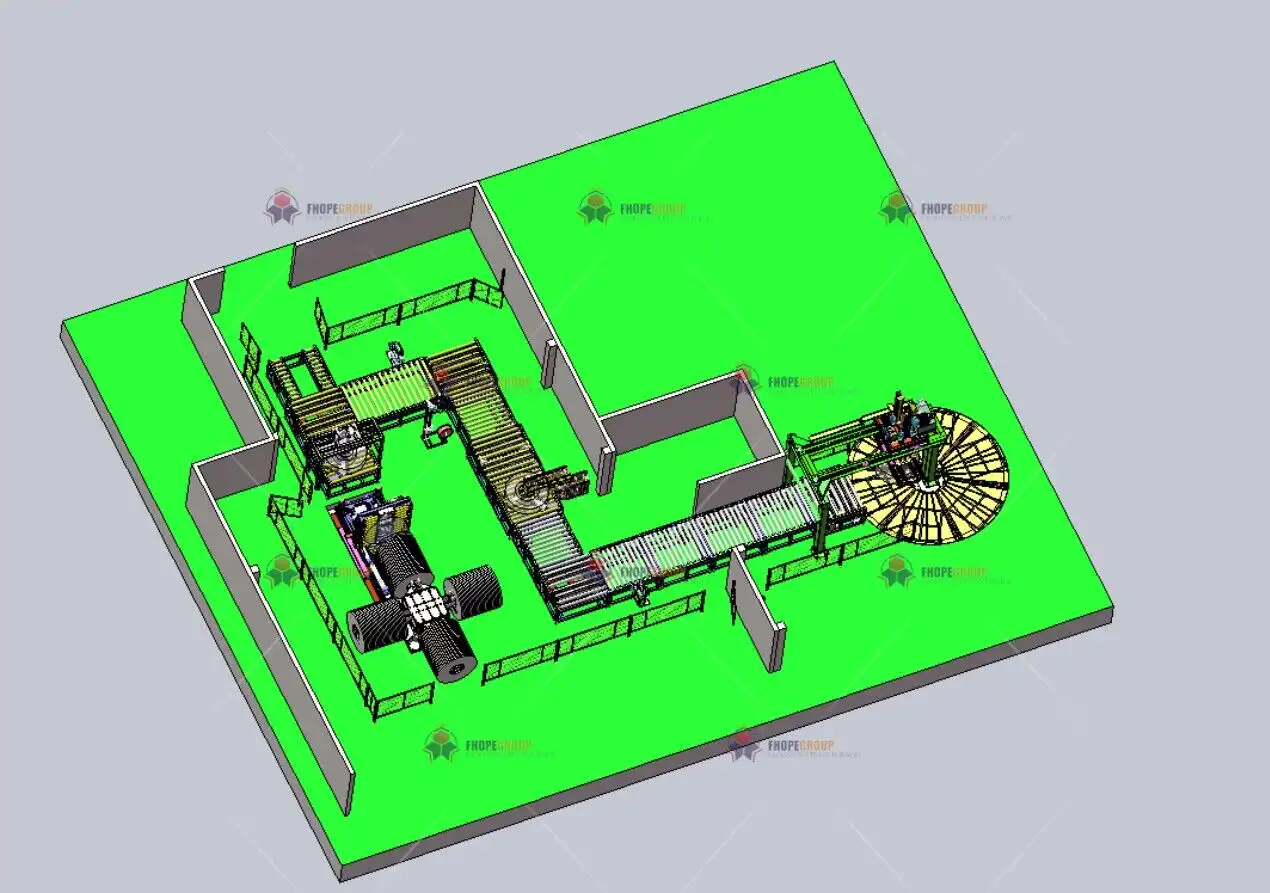

Automatic Slit Coil Packaging System

Discover the FHOPE Automatic Slit Coil Packaging System for efficient, safe handling of steel coils. Features turntable, strapping, and stacking equipment to minimize manual operations.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The Automatic Slit Coil Packaging System by FHOPE is a comprehensive solution designed for handling and packaging slit coils in industrial settings. It integrates multiple components including a turntable, coil down ender, coil weighing machine, coil strapping machine, and stacking equipment to automate the process from centering conveyor to pallet. This system enhances safety and efficiency by reducing manual handling of heavy coils, ensuring smooth and reliable operations for steel coil stacking.

Key operations include coil movement to the in-feeding station, automatic centering and lifting, coil pick-up, and palletizing coils one by one on a pallet, followed by pallet out-feeding. The system is built to handle coils with precision, featuring components like a centering and lifting table for error correction and easy pick-up, a stacking machine with durable structure and protective features, and a conveyor station for out-feeding palletized coils.

Key Benefits

- Minimizes manual operation for enhanced safety and efficiency in handling heavy steel coils

- Includes turntable, coil down ender, weighing machine, strapping machine, and stacking equipment for full automation

- Features centering and lifting table with error correction and automatic coil positioning

- Stacking machine with strong forks, gantry type mechanism, and protective arms for smooth coil movement

- Conveyor station for out-feeding palletized coils with specified max stacking height and weight

Automatic Slit Coil Packaging System Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Max Horn Extension | Approximately 1800 mm |

| Linear Motion Slides/ Wheels/ Camrollers | By Linear |

| Cycle Time to Downend Coil | 60 seconds |

| Conveyor Length | 1600 mm |

| Covered Rollers Include | Roll diameter: 100 mm, length: 1600 mm, covering material: PU, Roll centers: 150 mm |

| Conveyor Motor | 2.2 kW |

| Max Stacking Height | 1000 mm (including pallet height) |

| Max Stacking Weight of Single Coil | 3000 kg |

| Stacking Platform | Conveyor |

Frequently Asked Questions

Common questions about Automatic Slit Coil Packaging System and our services.

Q:What components are included in the Automatic Slit Coil Packaging System?

Q:How does this system improve safety and efficiency?

Q:What are the key specifications for coil handling?

Related Products

Slit Coil Handling and Packaging Line

Economic Vertical Steel Slitting Coil Packaging Line

Automatic Slitting Coil Packaging Line with Turntable Stacker

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Slit Coil Packaging System and discover how it can optimize your operations.