Tap thumbnails to view different images

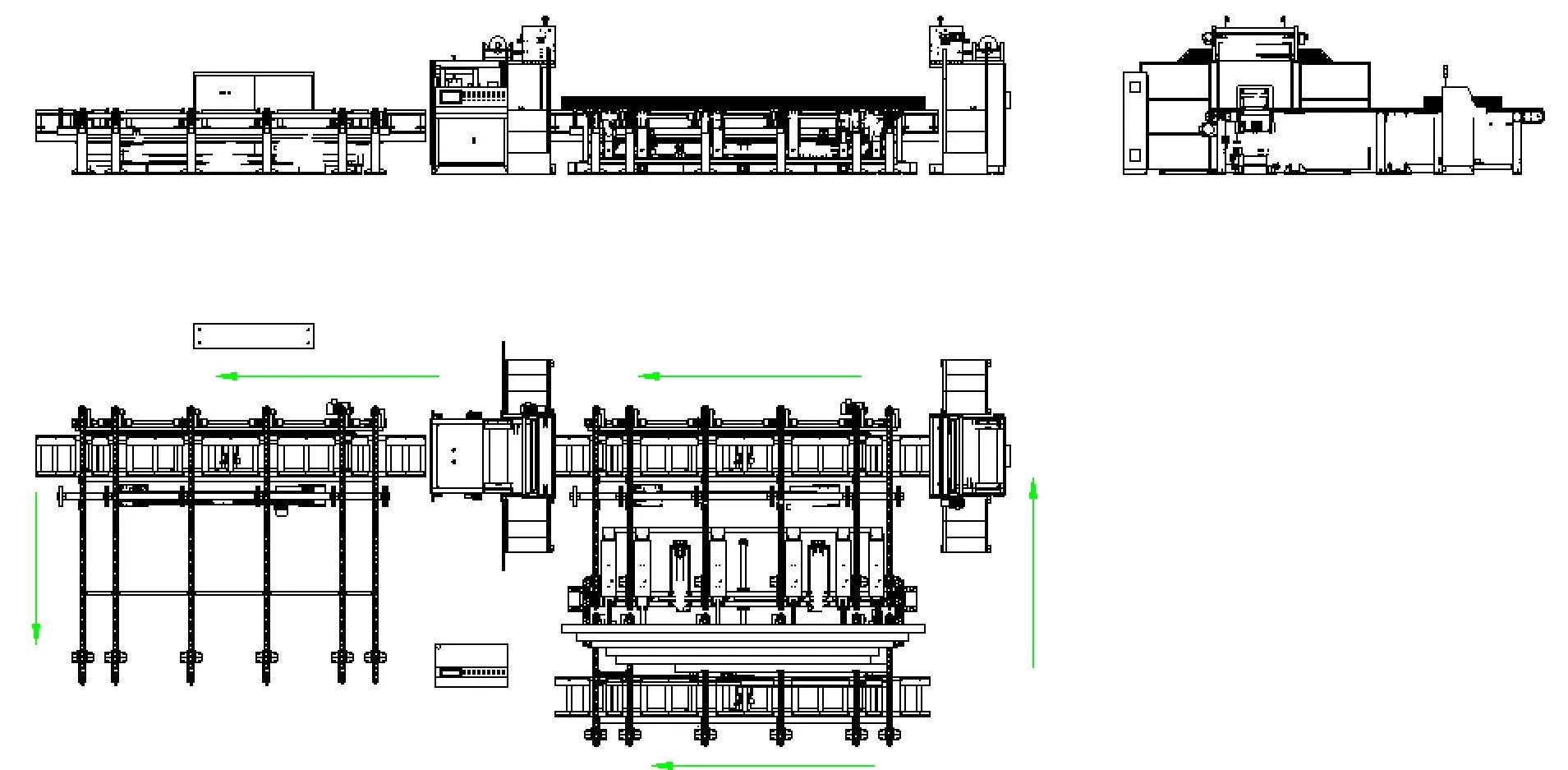

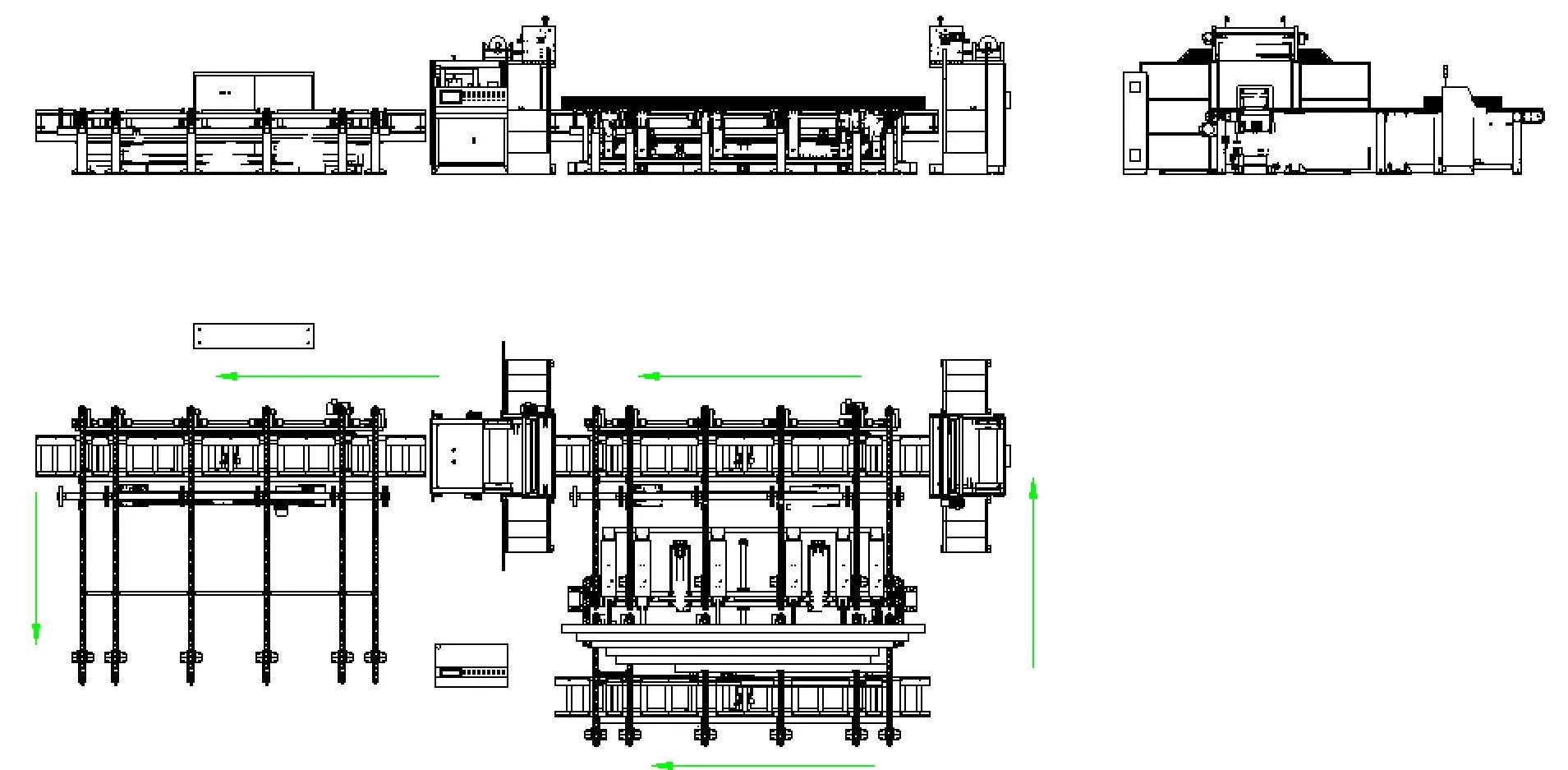

Automatic Rod Straightening and Strapping System

Boost productivity with our Automatic Rod Strapping Machine. Handles steel, aluminum, and alloy rods (6-50 mm) with PET or steel straps. Features automated workflow, adjustable tension, and seamless integration for secure, efficient packaging.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

In the industrial realm, where precision and speed define productivity, the Automatic Rod Strapping Machine emerges as a vital solution. Designed to handle steel rods, aluminum rods, and alloy rods with ease, this machine integrates bundling and strapping processes into a seamless automated system. Whether securing light loads with PET straps or heavy-duty bundles with steel belts, it offers tailored solutions to meet diverse packaging requirements. With automated infeeding conveyors, a strapping station, and outfeeding conveyors, this versatile system enhances operational efficiency while ensuring product integrity. Moreover, it can be seamlessly integrated with bundling and packing machines to achieve your unique packaging objectives.

The Automatic Rod Strapping Machine redefines packaging standards by combining versatility, automation, and precision. Ideal for industries ranging from construction to metal fabrication, it not only boosts productivity but also ensures your rods are packaged securely for transport or storage. By integrating with bundling and packing systems, this machine offers a complete solution for achieving your packaging goals with confidence and ease.

Key Benefits

- Versatile Strapping Solutions for PET and steel belts to handle varying bundle weights and protection levels

- Automated Workflow from infeeding to outfeeding for maximum efficiency and reduced manual intervention

- Adjustable Strapping Tension with customizable settings to secure rods without compromising integrity

- Seamless Integration with bundling and packing systems for unified packaging solutions

- Precision Strapping Station using advanced technology for accurate strap positioning and uniformity

- Eco-Friendly Operations compatible with recyclable PET strapping materials to reduce environmental impact

- Enhanced Safety Features including emergency stop buttons, protective enclosures, and real-time fault monitoring

- User-Friendly Interface with an intuitive control panel for easy adjustments and troubleshooting diagnostics

Technical Specifications

| Specification | Value |

|---|---|

| Strapping Material Options | PET Straps (10–19 mm), Steel Belts (12–32 mm) |

| Tension Range | 50–3000 N (adjustable) |

| Machine Dimensions | Approx. 4500 × 2200 × 2500 mm |

| Net Weight | ~2800 kg |

Frequently Asked Questions

Common questions about Automatic Rod Straightening and Strapping System and our services.

Q:What types of rods can this machine handle?

Q:Can the machine integrate with existing packaging systems?

Q:What safety features are included?

Related Products

Automatic Rod Bundling Machine

Automatic Rod Packing Machine

Customized Rod Packing System

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Rod Straightening and Strapping System and discover how it can optimize your operations.