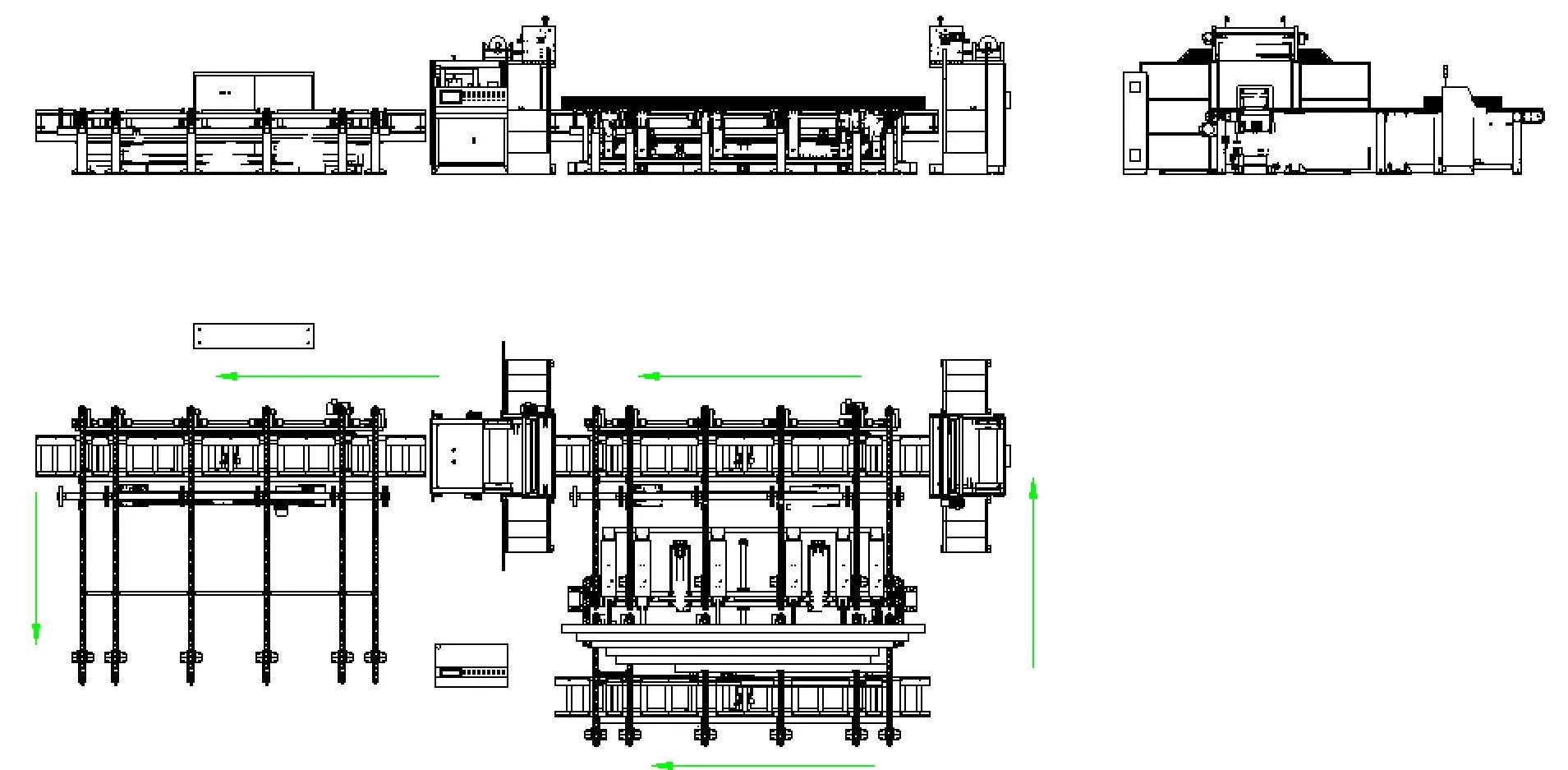

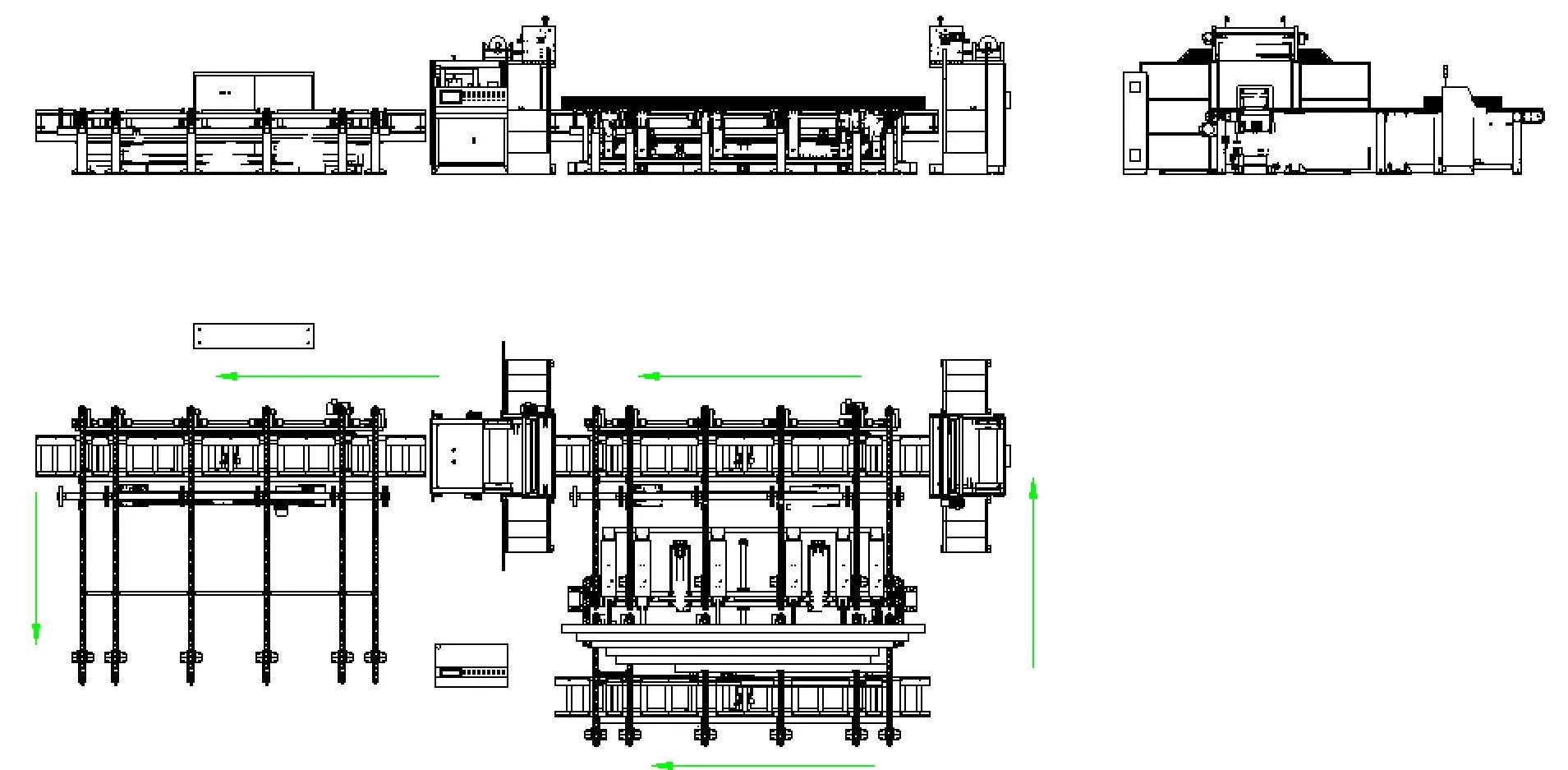

Automatic Rod Bundling Machine

Boost productivity with our Automatic Rod Bundling and Packing Line. Features automated counting, versatile material handling, and adaptive tension control for steel, aluminum, and alloy rods.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

In the ceaseless evolution of modern industry, precision and reliability often serve as the keystones of productivity. The Rod Bundling Machine stands at this intersection, engineered to organize steel rods, aluminum rods, and alloy rods into neatly stacked bundles. Whether you're tackling small-scale fabrication or large-scale metal-processing enterprises, this machine deftly counts each rod and forms layer-by-layer bundles with minimal human intervention. Beyond mere packaging, it ushers in a new era of swift, structured operation, blending robust automation with user-friendly control.

Standing at the crossroads of flexibility and efficiency, the Rod Bundling Machine underscores a commitment to organized workflow and meticulous engineering. From high-volume rolling mills to specialized rod-processing workshops, it seamlessly adapts, offering both speed and precision to match the rigorous demands of a cutting-edge production environment.

Key Benefits

- Automated Counting & Layering: Intelligent counting algorithm reduces miscounts and ensures seamless layer formation.

- Versatile Material Handling: Adapts to steel, aluminum, or alloy rods with consistent speed and accuracy.

- Adaptive Tension Control: Calibrates bundling force to secure bundles while maintaining rod integrity.

- User-Focused Interface: Touch-screen panel with intuitive diagnostics for quick setup and real-time monitoring.

- Swift Package Ejection: Smoothly releases finished bundles onto outfeed conveyors to reduce wait times.

- Reliable Safety Framework: Equipped with emergency stop functions, enclosure guards, and fault alerts for operator safety.

Technical Specifications

| Specification | Value |

|---|---|

| Counting Accuracy | ±1 rod per layer |

| Tension Range | 0–500 N (precisely adjustable) |

| Overall Dimensions | Approx. 3200 × 1800 × 2200 mm |

Frequently Asked Questions

Common questions about Automatic Rod Bundling Machine and our services.

Q:What types of rods can the Automatic Rod Bundling and Packing Line handle?

Q:How does the machine ensure accurate counting and bundling?

Q:What safety features are included in the Rod Bundling Machine?

Related Products

Automatic Rod Packing Machine

Automatic Rod Straightening and Strapping System

Customized Rod Packing System

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Rod Bundling Machine and discover how it can optimize your operations.