Tap thumbnails to view different images

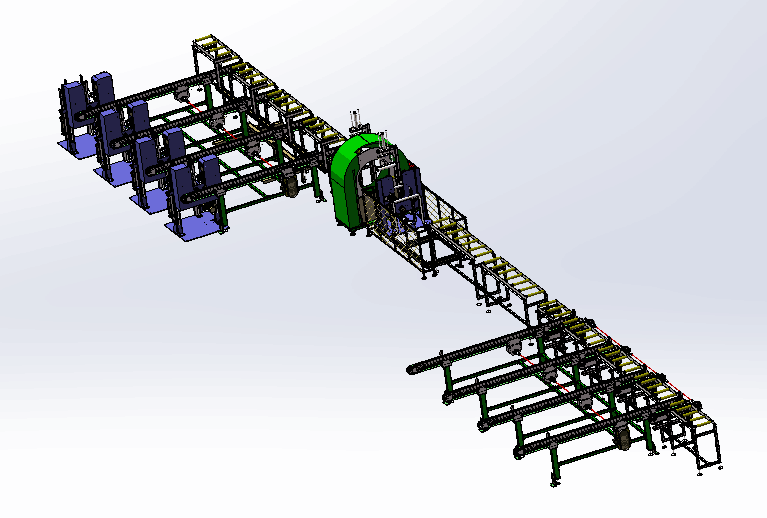

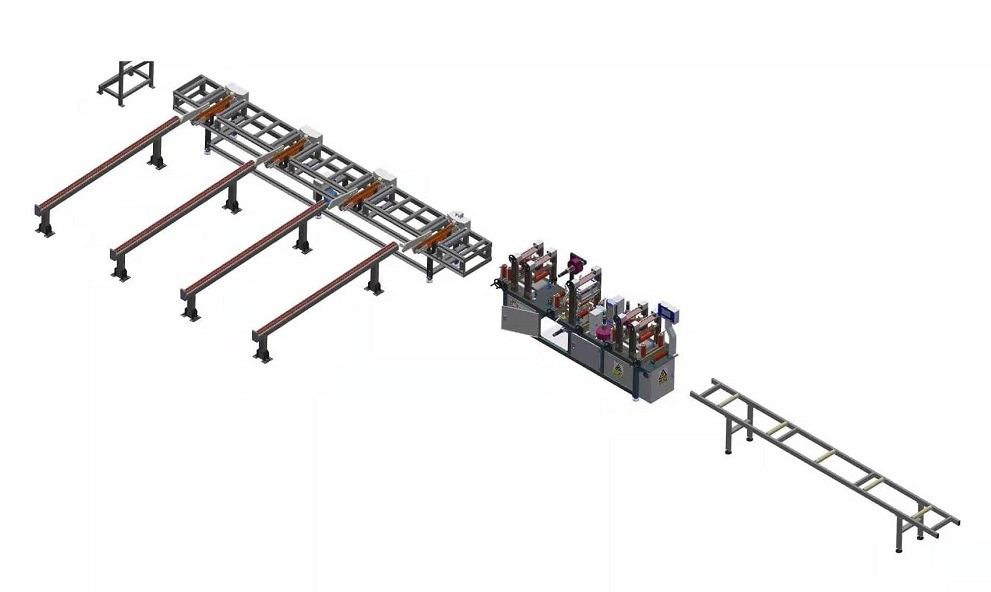

Automatic Aluminum Profile Wrapping and Tapping Machine

Advanced aluminum profile wrapping and tapping machine for automated packaging with paper and film. Features automatic strapping, transfer belts, and synchronized tapping to enhance efficiency and protect profiles.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

This advanced equipment is designed for aluminum profile wrapping, capable of handling paper and stretch film, with integrated tapping as a key feature. The tapping process operates automatically during profile movement and wrapping, controlled by a system for seamless packaging.

The machine includes a sub-bundle strapping machine with a transfer belt, featuring three to four wrapping stations where workers load profile bundles onto a platform. Automatic positioning occurs before strapping, and a lifter handles bundles post-strapping. A rotating ring holds the wrapping film roll on a mandrel with a special clutch to maintain constant tension, with speed regulated by an electronic inverter. An automatic device stops the machine and alerts the operator if the roll runs out or the material tears, operating in start-stop mode with a blade cutting the material at each cycle end, adjustable to user needs.

Reinforced transfer belts transport sub-bundles to the in-feed roller table of the sub-bundle wrapping machine, depositing packs only when the table is free. The sub-bundle wrapping machine uses a powered roller table for profile transport, with centering rollers to keep profiles aligned. It performs spiral wrapping with 25-micron thick stretch film, fully automatic from ring start to completion, with transfer rollers moving profiles during wrapping and a mechanical hand cutting the material upon exit. A material draw-back device ensures constant tension, and coated rollers protect profiles from damage.

An automatic tape banding machine is included for end tapping of aluminum packages to prevent paper loss after cutting, connecting to the profile wrapping machine for synchronized online packaging.

Key Benefits

- Automatic tapping synchronized with wrapping process

- Sub-bundle strapping with transfer belt for efficient transport

- Spiral wrapping using 25-micron stretch film for protection

- Electronic inverter for adjustable speed control

- Automatic stop and alert system for material issues

- Coated rollers to prevent profile damage during handling

Automatic Aluminum Profile Wrapping and Tapping Machine Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Safety Features | Automatic stop for material tear or roll out |

| Operation Mode | Start and stop with cycle-end cutting |

| Transport System | Powered roller table with centering rollers |

| Additional Function | Automatic tape banding for end tapping |

Frequently Asked Questions

Common questions about Automatic Aluminum Profile Wrapping and Tapping Machine and our services.

Q:What materials can this machine wrap?

Q:How does the automatic tapping feature work?

Q:Is the machine fully automatic?

Related Products

Automated Extruded Aluminum Profile Packaging Line

Automatic Aluminum Profile Protective Film Applicator

Automated Aluminum Profile Packing Line with Integrated Timber Feeder

Automated Aluminum Profile Paper & Film Wrapping System

Ready to Upgrade Your Production Line?

Get a customized quote for Automatic Aluminum Profile Wrapping and Tapping Machine and discover how it can optimize your operations.