Tap thumbnails to view different images

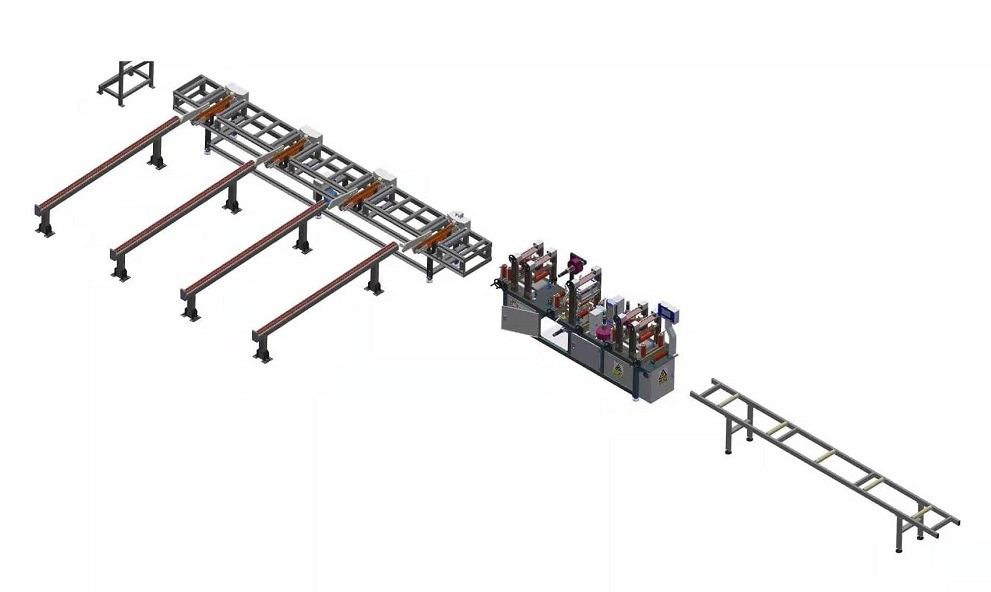

Automated Aluminum Profile Packing Line with Integrated Timber Feeder

Automated aluminum profile packing line with timber feeder for efficient bundle wrapping. Features compact steel frame, automatic rollers, and PLC control for seamless operation.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

This aluminum profile packing line is designed with a compact steel frame for durability and ease of use. It features an automatic timber feeder that efficiently places wooden blocks on top and bottom of bundles, enhancing stability. The machine uses a series of rollers that open and close automatically, allowing bundles of varying dimensions to pass through without stopping, ensuring continuous operation. Wrapping material replacement is quick and simple, and the entire process is fully automated with PLC control and photoelectric induction for precise handling.

The line includes a powered roller table with centering rollers to maintain profile alignment, a spiral wrapping machine that uses 25-micron stretch film for secure packaging, and a material draw-back device for constant tension. The conveyor system protects profile surfaces from damage, and the timber feeding station can be adjusted for different product heights and integrated with the wrapping station for flexible packing needs. This setup guarantees stable, compact bundles with minimal operator intervention.

Key Benefits

- Automatic timber feeder for top and bottom placement of wooden blocks

- Compact steel frame design for durability and easy maintenance

- Automatic rollers that adjust to different bundle sizes without stopping

- PLC-controlled operation with photoelectric induction for accuracy

- Spiral wrapping machine using 25-micron stretch film for secure packaging

- Powered roller table with centering rollers for precise profile alignment

- Material draw-back device ensures constant tension during wrapping

- Conveyor system protects aluminum profiles from surface damage

- Adjustable timber feeding height to accommodate various product sizes

- Integrated wrapping station for seamless and flexible packing operations

Automated Aluminum Profile Packing Line with Integrated Timber Feeder Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Operator Requirement | 1 person for aluminum profile bundle feeding |

| Wrapping Film Thickness | 25 micron |

| Timber Feeding | Automatic, adjustable height |

| Machine Frame | Compact steel construction |

| Operation Mode | Fully automatic |

Frequently Asked Questions

Common questions about Automated Aluminum Profile Packing Line with Integrated Timber Feeder and our services.

Q:What is the primary application of this packing line?

Q:How does the automatic timber feeder work?

Q:What are the size limitations for bundles?

Q:Is the wrapping process fully automated?

Q:How many operators are required to run this line?

Related Products

Automated Extruded Aluminum Profile Packaging Line

Automatic Aluminum Profile Protective Film Applicator

Automated Aluminum Profile Paper & Film Wrapping System

Automatic Aluminum Profile Stacking Machine

Ready to Upgrade Your Production Line?

Get a customized quote for Automated Aluminum Profile Packing Line with Integrated Timber Feeder and discover how it can optimize your operations.