Tap thumbnails to view different images

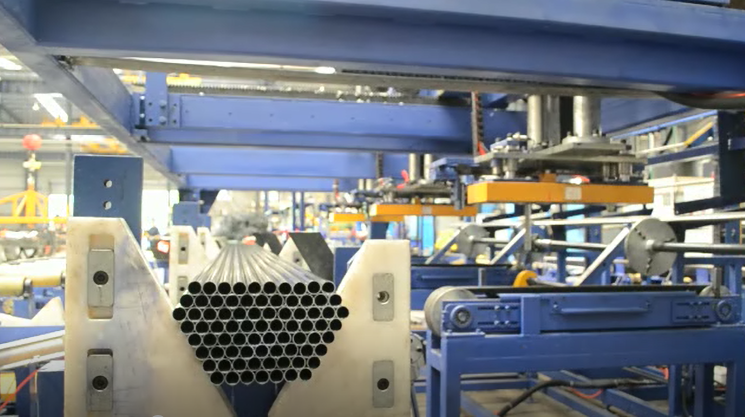

Automated Magnetic Steel Pipe Bundle Packing Line

Discover our fully automated steel pipe bundling and packing line system, featuring touch screen control, adjustable forming, and seamless integration for enhanced productivity in B2B operations.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The FHOPE Bundling Station is designed to handle and bundle steel pipes or hollow structural sections into precisely sized bundles, tailored to product dimensions. This fully automated system is controlled from a touch screen operator station, ensuring efficient and reliable operation. The bundling machine constructs programmed configurations, securely containing sides to maintain shape until strapping is complete. Once bundled, a lateral transfer system stages the bundles onto an unloading table for final transfer, streamlining the packaging process.

The system integrates multiple stages including run-out roller conveyor, rejection kicking, waster pipes collection, tube picking with air blower, aligning, counting, rectangular tube auto-detection with 90-degree flipping, row layering, bundling, shifting to conveyor, manual strapping, bundling air blower, auto bundles out-loading conveyor, and 5 bundles chain stacking, providing a comprehensive solution for industrial pipe handling.

Key Benefits

- Electromagnetic chuck type row stacking layers bundling system for secure handling

- Adjustable forming device to accommodate different bundle shapes and sizes

- Tube movement to bundling position via pushing mechanism for precise alignment

- Tube stacking stopper pushes out to maintain bundle integrity during processing

- Tube bundling stopper pushes out and clamps tube rows tightly to prevent loosening

- Supporting forks reset to ensure stable and efficient bundling operations

- Integrated electric control system with automatic, semi-automatic, and manual modes for flexible management

Automated Magnetic Steel Pipe Bundle Packing Line Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Tube Movement | Pushing mechanism to bundling position |

| Stopper Functions | Stacking and bundling stoppers for clamping and protection |

| Transfer System | Lateral transfer to unloading table |

| Integration Stages | Run-out conveyor, rejection kicking, aligning, counting, layering, bundling, strapping, out-loading conveyor, chain stacking |

Frequently Asked Questions

Common questions about Automated Magnetic Steel Pipe Bundle Packing Line and our services.

Q:What types of materials can this bundling system handle?

Q:How is the system controlled and operated?

Q:What are the key stages in the bundling process?

Related Products

Automatic Pipe and Tube Bundling & Strapping Line

Automatic Steel Tube Strapping Machine

FHOPE Automatic Steel Tube Packaging Machine

FHOPE Automated Steel Tube & Profile Bundling Line

Ready to Upgrade Your Production Line?

Get a customized quote for Automated Magnetic Steel Pipe Bundle Packing Line and discover how it can optimize your operations.