Tap thumbnails to view different images

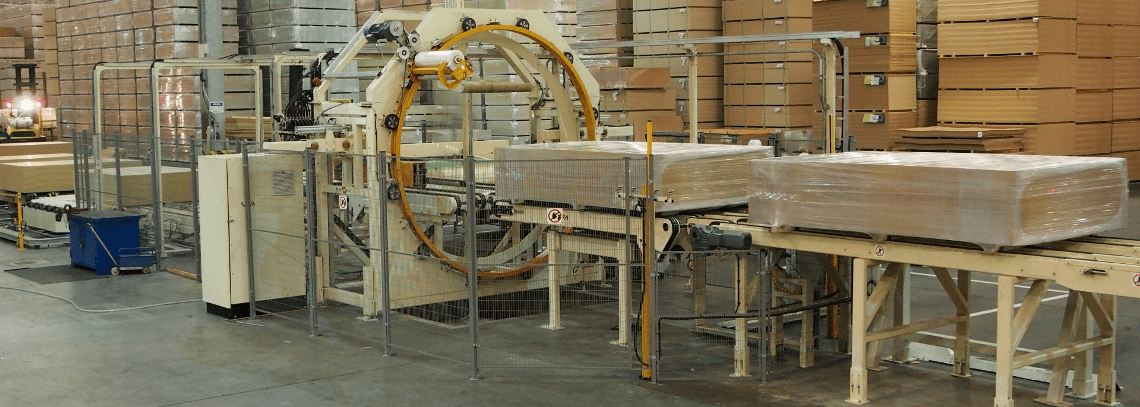

Orbital Horizontal Stretch Wrapper with Integrated Bubble Film Sealing System

Discover the automatic orbital stretch wrapper with bubble film for secure, efficient packaging. Features PLC control, adjustable sealing, and handles various product sizes. Ideal for industrial use.

Key Specifications

Custom Engineering Available

Need modifications? Our team can tailor this solution to your specific requirements.

Product Description

The Orbital Stretch Wrapper with Bubble Film is an advanced automatic packaging solution designed for industrial applications. It combines stretch film and bubble film to provide superior protection for products during transit and storage. This machine features a horizontal wrapping mechanism with an integrated sealing station, offering reliable and efficient packaging for a wide range of product dimensions.

Equipped with PLC control and adjustable settings, it ensures precise operation and adaptability to different packaging needs. The system includes automatic sealing, conveyor speed adjustment via inverters, and constant temperature heat sealing for consistent results. Ideal for businesses seeking to enhance packaging productivity and product safety.

Key Benefits

- Automatic sealing station with photo-electric induction for precise product positioning

- Adjustable sealing height and conveyor speed for versatile packaging applications

- PLC-controlled constant temperature heat sealing system for reliable performance

- Compatible with both bubble film and stretch film for enhanced protection

- Two feed-in modes (auto/manual) and easy-exchangeable sealing blades for flexibility

Orbital Horizontal Stretch Wrapper with Integrated Bubble Film Sealing System Video

Watch our product demonstration to see the machine in action. Discover how it can improve your production efficiency and packaging quality.

Technical Specifications

| Specification | Value |

|---|---|

| Structure Material | Carbon steel |

| Packing Objects | Length: 900-2400mm, Width: 200-1200mm, Height: 100-800mm, Weight: 20-100kg |

| Height Of Working Table | Approximately 800mm |

| Packing Material | Bubble film + stretch film |

| Air Supply | 6-8 kgf/cm² |

| In-feed Conveyor | 2000mm L × 1400mm W |

| Out-feed Conveyor | 2000mm L × 1400mm W |

| Material Stretch Film | LLDPE, Width: 150-500mm, OD: 100-200mm, ID: 50mm |

| Material Bubble Film | Width: 20-1300mm, OD: 50-600mm |

| Conveyor Size | Approximately L 4500mm × W 1600mm × H 900mm |

| Power Output | Approximately 3.5 KW |

| Power Voltage | AC 230V, 50Hz/60Hz, 3-phase |

| Control Power Voltage | ADC 24V |

Frequently Asked Questions

Common questions about Orbital Horizontal Stretch Wrapper with Integrated Bubble Film Sealing System and our services.

Q:What types of products can this orbital stretch wrapper handle?

Q:How does the automatic sealing station work?

Q:What are the power requirements for this machine?

Related Products

Six-Sided Horizontal Orbital Stretch Wrapper for Panel & Board Packaging

Horizontal Orbital Pipe Wrapping Machine

Fhope-F Series Horizontal Orbital Stretch Wrapping Machine

Aluminum Horizontal Orbital Wrapping Machine

Ready to Upgrade Your Production Line?

Get a customized quote for Orbital Horizontal Stretch Wrapper with Integrated Bubble Film Sealing System and discover how it can optimize your operations.